In the world of chemistry, the metallic element samarium has long been recognized for its potential in synthesizing molecules that can lead to the creation of new pharmaceuticals. However, a major challenge has always been scaling up the use of samarium reagents for industrial applications. Traditionally, the reagent would need to be freshly prepared before each reaction, making it impractical for large-scale operations. But recent research from Caltech has unveiled a groundbreaking solution that allows samarium diiodide reagent to recycle itself for repeated use, eliminating the need for constant fresh preparations and large amounts of solvents.

The study, titled “Reductive samarium (electro)catalysis enabled by SmIII-alkoxide protonolysis,” published in the journal Science, details how Caltech chemists have managed to overcome the limitations of the samarium reagent. The breakthrough has opened up a world of possibilities for utilizing this versatile reagent in industrial settings, where previously it was restricted to lab use only. By finding a way to break down the pesky samarium-oxygen bond that rendered the reagent inactive, the researchers have unlocked the potential for samarium diiodide to be used on a larger scale.

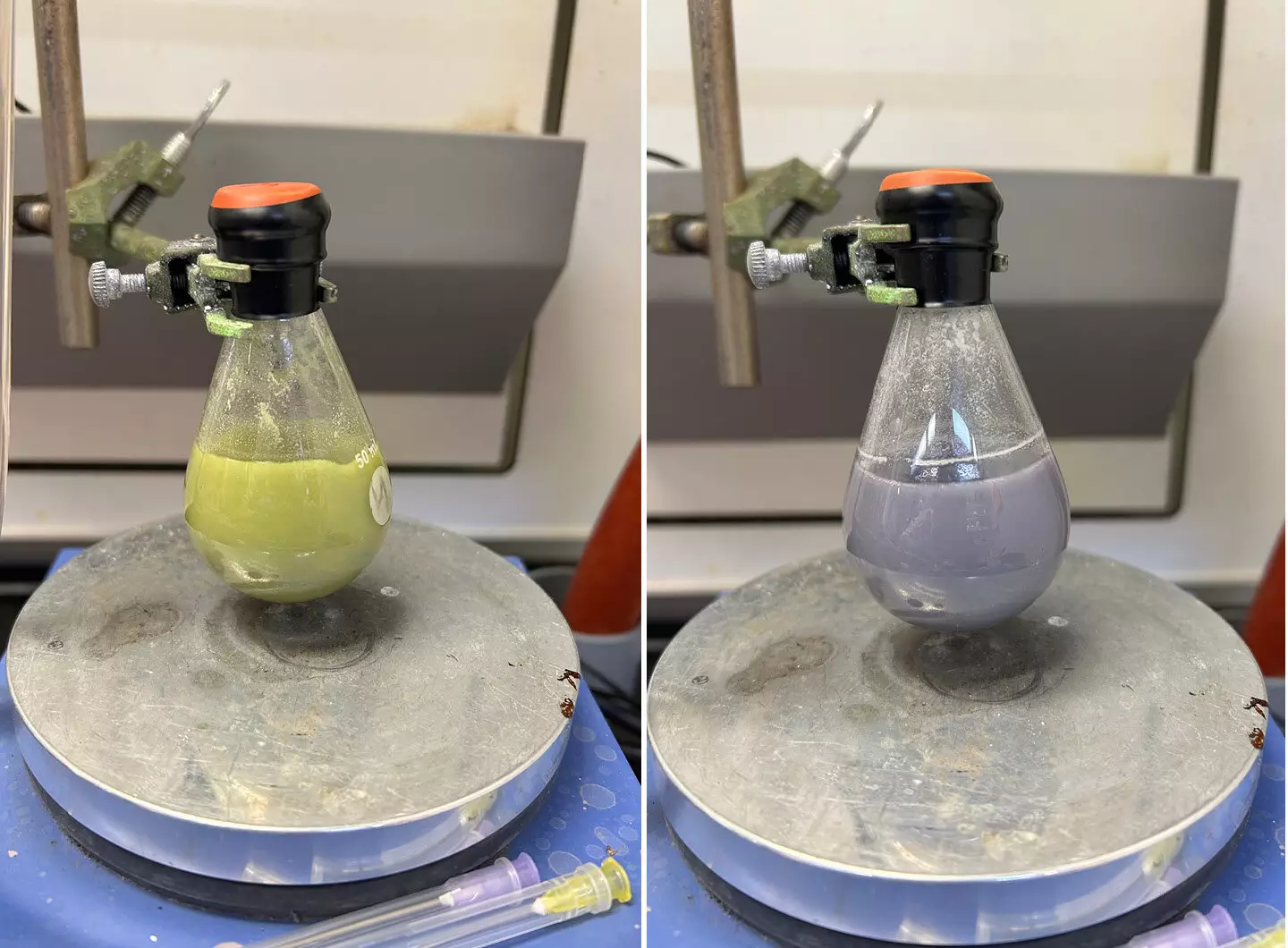

One of the key obstacles in using samarium reagents in industrial applications has been the formation of a strong samarium-oxygen bond during reactions, which inhibits the reagent from being recycled. Previous attempts to break this bond involved harsh chemicals, making it impractical for large-scale reactions. However, the Caltech researchers were able to cleverly cleave the bond using a mild acid, allowing the samarium reagent to return to its active state and be used repeatedly in a single reaction. This innovative approach not only streamlines the process but also makes it more environmentally friendly.

The success of this groundbreaking research was the result of collaboration between different research groups at Caltech. Graduate students Emily Boyd and Chungkeun Shin, along with their respective research labs led by professors Sarah Reisman and Jonas Peters, worked together to tackle the challenges associated with samarium reagents. By combining their expertise in organic synthesis and catalysis, the team was able to develop a practical and efficient method for recycling the reagent, paving the way for its industrial application.

The implications of this research are far-reaching, particularly in the field of pharmaceutical development. With the ability to recycle samarium reagents for industrial use, the synthesis of new pharmaceutical compounds can now be more efficient and cost-effective. This opens up possibilities for creating a wide range of medications on a larger scale, potentially revolutionizing the pharmaceutical industry. Additionally, the environmentally friendly approach of using mild acids to cleave the samarium-oxygen bond aligns with the growing emphasis on sustainable practices in chemical manufacturing.

The breakthrough discovery by Caltech chemists to recycle samarium reagents for industrial use represents a significant advancement in the field of organic synthesis. By overcoming the challenges associated with scaling up the use of samarium diiodide, the researchers have paved the way for more efficient and sustainable chemical reactions. The collaborative efforts of the research teams involved have demonstrated the power of interdisciplinary approaches in solving complex scientific problems. As this research continues to progress, we can expect to see further innovations in pharmaceutical development and chemical manufacturing that leverage the unique properties of samarium reagents.

Leave a Reply