In the realm of materials science, the intricate relationship between microstructure and material properties is pivotal. Understanding how various microstructural characteristics can affect the performance of materials is crucial for the advancement of next-generation structural and functional materials. This imperative task, however, is fraught with complexity. Traditional methods often fall short in their capability to effectively correlate microstructure features with the resultant properties, leaving researchers in search of innovative approaches to bridge this gap.

A Breakthrough Computational Framework

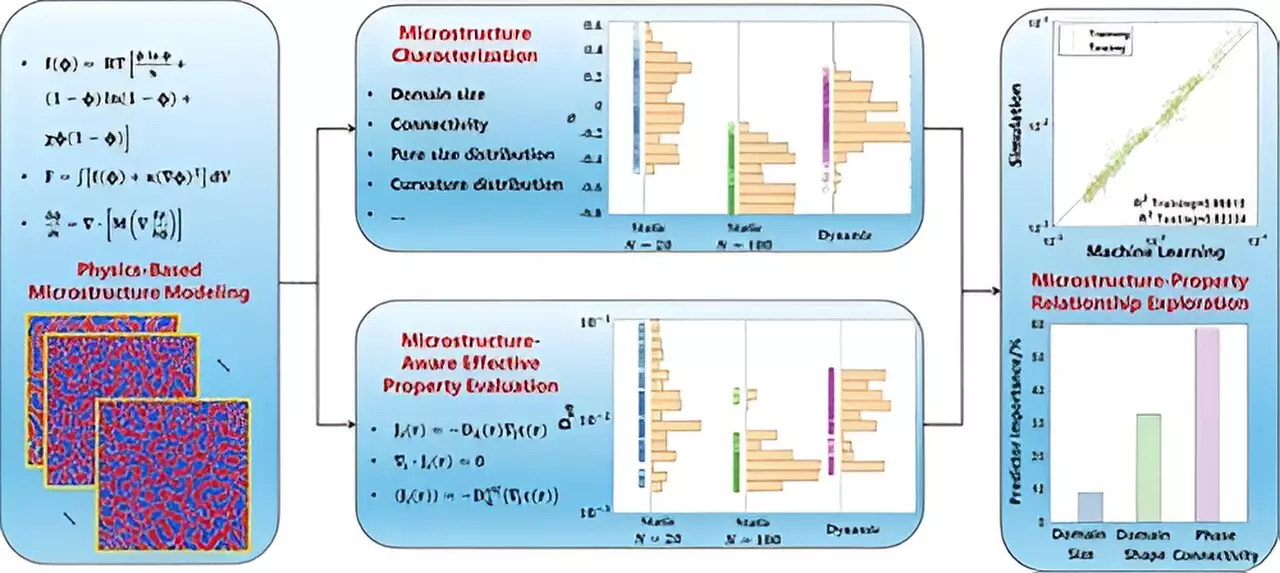

To tackle these challenges, scientists from Lawrence Livermore National Laboratory (LLNL) have created an advanced computational framework designed to unravel the complexities of porous microstructures and their associated properties. Their groundbreaking research has been published in the esteemed journal ACS Applied Materials & Interfaces. The lead author, Longsheng Feng, a prominent scientist at LLNL, highlighted the framework’s comprehensive nature, which integrates several critical components. This includes physics-based modeling to represent microstructures, feature extraction techniques to analyze those structures, and effective property evaluation methodologies complemented by machine learning analysis.

This integrative approach allows researchers to not only construct realistic microstructure representations but also derive meaningful insights into how specific features contribute to various material properties. This is particularly relevant for polymer-based porous materials, a model system through which the team illustrated the framework’s utility.

Feng and his team concentrated their efforts on exploring the influence of polymerization dynamics on key microstructural features such as domain size and pore size distribution. These features are vital for understanding the transport properties of the materials in question. By employing this computational framework, the researchers successfully characterized the relationship between microstructural variations and resultant material behavior. Co-author Tae Wook Heo emphasized that the intent behind this innovative framework is not only to eye the formation processes of microstructures but to discern how distinct features can dictate specific material properties.

This dual focus highlights a significant advancement in the field—providing the means to predict how adjustments in processing techniques can yield tailored microstructures, which subsequently lead to the desired properties of polymeric porous materials.

The potential applications of this research are vast, particularly in the development of advanced materials for critical applications such as membranes. Juergen Biener, another LLNL scientist involved in the project, pointed out that insights gleaned from understanding microstructure-property relationships can inform better processing methods. This capacity to optimize material properties by guiding the fabrication of specific microstructures heralds a new chapter in materials science, where precision engineering of materials is possible.

The work conducted by the LLNL team marks a significant leap forward in the field of materials science. By bridging the gap between microstructure features and material properties, their comprehensive computational framework opens pathways for exciting innovations in material design, paving the way for high-performance applications across various industries.

Leave a Reply