Throughout history, blacksmiths have intuitively harnessed the power of work hardening—a process whereby metals, when subjected to deformation through bending or hammering, gain strength. This age-old technique, foundational in metallurgy, continues to hold significant relevance in contemporary manufacturing processes, enhancing the durability of products ranging from automotive components to infrastructural elements like power lines. Recent advancements in materials science, however, have allowed researchers to delve deeper into this intricate phenomenon, revealing complexities previously veiled by technological limitations.

Groundbreaking Observations in Real-Time

The significant breakthrough emerged from the collaborative efforts of scientists at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS). For the first time, researchers have been able to observe the nuanced processes driving work hardening in real time. By focusing on the detailed atomic behaviors during deformation, the study published in *Nature* offers invaluable insights that could reshape our understanding of material strength, with implications that echo across various sectors engaged in material design and production.

Frans Spaepen, a prominent figure in the research and a professor of applied physics at SEAS, elucidated the critical nature of this work: “Today, large-scale computer programs are used to model work hardening, but if you want these models to be truly effective, we require a deeper understanding of the governing laws.” The undertaking aimed to unravel the fundamental mechanisms underlying this universal yet complex process.

Historically, capturing the work hardening process within metals during deformation posed a significant challenge. Traditional methods allowed for comparative analyses of atomic structures before and after the process, offering mere snapshots instead of a dynamic view of the transformation. Researchers identified that imperfections—referred to as dislocations—created networks of defects that drove the work hardening, but comprehending the multiplicity and nuance of these interactions remained elusive.

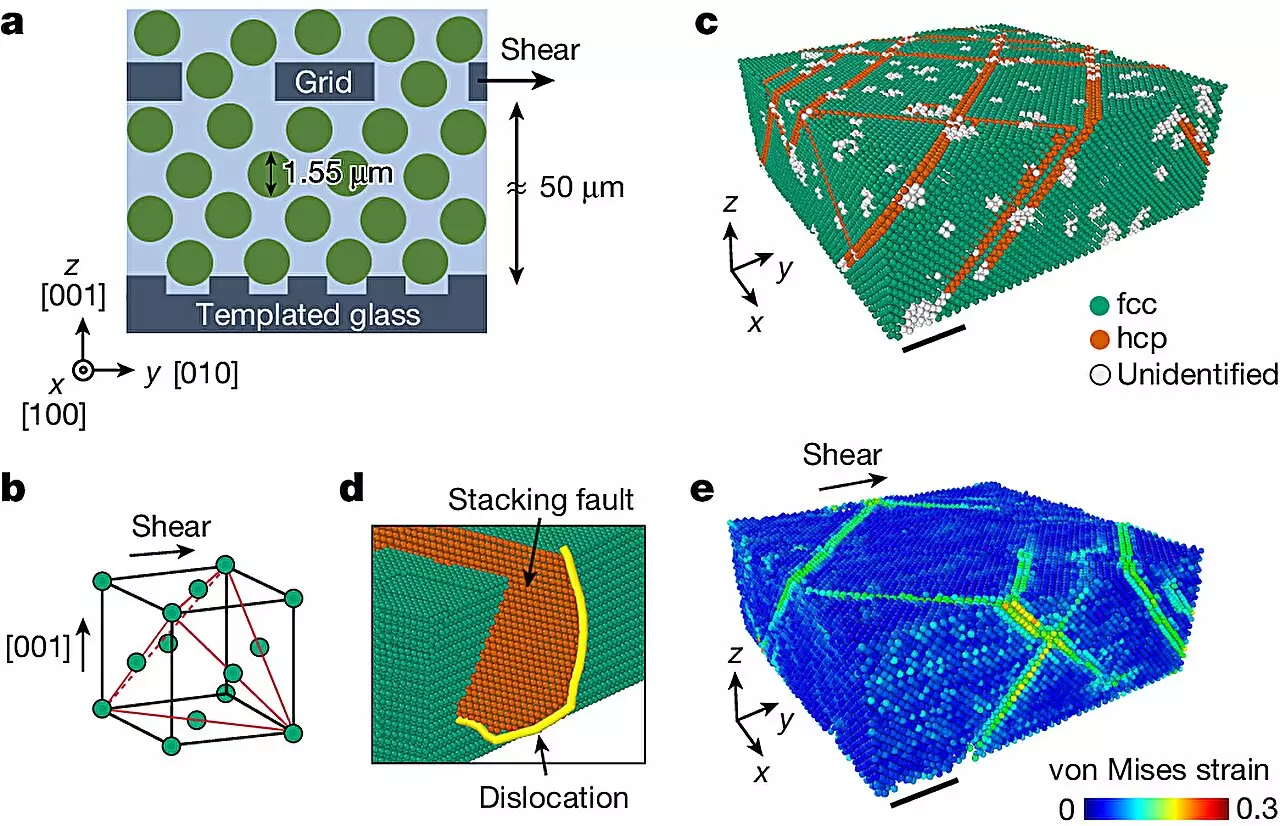

To overcome the limitations imposed by conventional methods, researchers sought to explore a more manageable analog: colloidal crystals—particles approximately 10,000 times larger than atoms. Interestingly, these larger structures replicate essential physical behaviors of atomic systems, embracing similar configurations and phase transitions while showcasing characteristic defects.

The Role of Colloidal Crystals

In this groundbreaking study, the researchers utilized colloidal crystals, which are notably soft, with mechanical strengths significantly lower than standard metals. By fabricating these crystals from millions of individual particles, the team employed confocal optical microscopy to monitor particle movements under applied strain. This process permitted a real-time assessment of deformation, revealing unprecedented levels of work hardening.

Unexpectedly, colloidal crystals demonstrated an extraordinary capability for strengthening under stress, outperforming many conventional metals, including copper and aluminum, when particle size discrepancies were accounted for. As Seongsoo Kim, a key graduate student in the research team, remarked, “We did not predict that hard-sphere colloidal crystals could exhibit work hardening, particularly given their simple particle interactions.”

This research marks the inaugural observation of work hardening within colloidal systems, shedding light on how particle geometry and defect interactions dictate material strength. The pronounced increase in strength is attributed to how dislocation defects engage and become entangled during deformation. The density of these defects in the colloidal crystals plays a crucial role, contributing to an extraordinary resistance to stress, far exceeding initial expectations.

David A. Weitz, a professor of physics and applied physics and a co-author of the paper, highlighted the significance of these findings: “This research reveals fundamental truths about the mechanisms through which materials achieve strength. The remarkable resilience of these soft materials is truly astonishing.”

Implications for Material Science

The implications of this research extend beyond colloidal crystals, offering profound insights applicable to a range of materials, whether or not they can be examined using optical methods. The study provides a framework for understanding material behavior under deformation, allowing for the optimization of material designs across various industries.

As the journey of materials science continues to unfold, these revelations about work hardening invite further investigation into the foundational principles of strength in all materials, ultimately guiding future innovations in manufacturing and engineering practices.

Leave a Reply