Recent advancements in high-temperature superconducting (HTS) wire technology are poised to redefine the landscape of energy efficiency, fundamentally reshaping how power is generated and transmitted. The ability of these HTS wires to carry electricity without resistance at higher temperatures than traditional superconductors has captured the attention of researchers and energy entrepreneurs alike. This paradigm shift could catalyze widespread changes in our electric power grid, unlocking incredible potential—from enhancing renewable energy technologies to facilitating commercial nuclear fusion.

The significance of research emerging from the University at Buffalo cannot be overstated. The team has successfully fabricated the world’s highest-performing HTS wire segment made from rare-earth barium copper oxide (REBCO). What’s particularly exciting is that this innovation does not just outperform previous technologies; it also presents a more enticing price-performance ratio. As energy demands continue to rise globally, these advancements could enable more efficient electric grids capable of supporting sustainable energy practices.

Performance Metrics on the Rise

The recent findings reveal that these new HTS wire segments showcase unprecedented critical current density and pinning force capabilities across a broad range of temperatures and magnetic fields. While the operational temperatures, ranging from 5 Kelvin to 77 Kelvin, remain on the extreme low end—comprising a staggering -451°F to -321°F—they are comparatively warmer than the absolute zero temperature that dictates traditional superconductive functionalities. Such advancements indicate substantial improvements in how electrical currents can be stored and transmitted, shaping up a future where energy loss becomes negligible.

This revolutionary wire achieved an impressive carrying capacity of 190 million amps per square centimeter at self-field conditions and 90 million amps per square centimeter under a magnetic field of 7 tesla at the near-cryogenic temperatures of 4.2 Kelvin. When we consider a targeted temperature of 20 Kelvin, commonly envisaged for commercial nuclear fusion applications, the carrying capacity only marginally decreases, still boasting over 150 million amps per square centimeter self-field and around 60 million amps at 7 tesla. Such statistics are not merely numbers; they represent a critical step toward solving global energy crises.

A Catalyst for Commercial Integration

According to Amit Goyal, the leading author of the research, these results serve as a critical template for industries seeking to optimize their fabrication techniques and enhance the price-performance metric of commercial coated conductors. This could not be more timely, as the growing demand for clean energy channels billions of dollars into the development of HTS wires. While commercial nuclear fusion remains an ambitious application, the benefits of HTS technology extend into diverse sectors, from offshore wind farms to advanced healthcare diagnostics.

Projects aiming to harness the potential of HTS wires are already springing up. The technology promises to enhance energy generation capabilities, notably by doubling the power output of offshore wind generators and minimizing the energy loss in energy transmission across high-speed current lines. The implication of this technology even reaches into the development of all-electric ships and aircraft, which could significantly diminish reliance on fossil fuels.

Innovation Through Collaboration

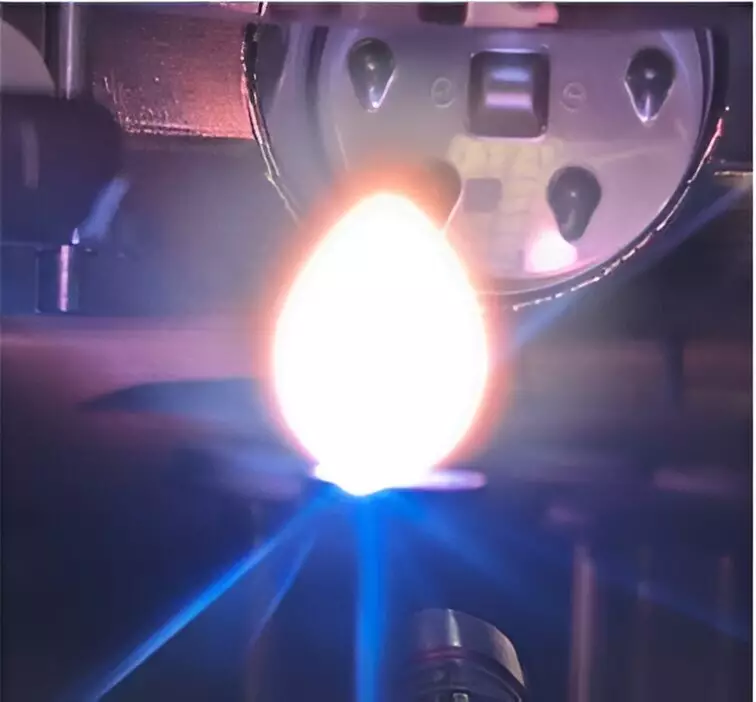

Historically, much of the progress in developing HTS wires stemmed from collaborative technologies pioneered by researchers like Goyal and his team. Among these innovations are the rolling-assisted biaxially textured substrates (RABiTS) and ion-beam-assisted deposition technology, which further enable the creation of high-quality superconducting materials. The recent research into nanocolumnar defects via self-assembly represents another leap forward, allowing for the manipulation of superconducting characteristics at the nanoscale to enhance performance metrics.

The confluence of advanced methodologies, including pulsed laser deposition and careful control of deposition parameters, not only yields thin films measuring a mere 0.2 microns but allows these films to deliver current densities comparable to wires several times thicker. This sophisticated approach encapsulates both the challenges and solutions inherent in modern superconductivity research.

Future Applications and Impact

HTS wires are not merely a scientific curiosity; they are at the forefront of real-world applications that promise to facilitate a more sustainable and efficient future. Beyond energy applications, the technology also stands to influence medical imaging advances through more powerful next-generation MRI machines and the development of high-field magnets for diverse physics applications. Moreover, with increased interest from the defense sector, HTS wires could play a pivotal role in developing next-generation military technologies.

While this research embarks us on a promising path toward a more energy-efficient future, the journey to commercialization still requires concerted efforts in reducing costs through optimized designs. As industry leaders mobilize to adopt these innovations, the hope is that we are on the brink of unlocking new forms of clean, efficient energy solutions that render outdated methodologies obsolete. There lies a palpable excitement regarding what tomorrow may hold with the continuous evolution of HTS wire technology, pointing toward a bright, sustainable future.

Leave a Reply