The evolution of electric vehicles (EVs) is fundamentally intertwined with advancements in battery technology, particularly in the quest for innovative energy storage solutions that enhance vehicle performance and longevity. Among the promising developments in this realm is the concept of structural batteries, a dual-purpose technology that integrates energy storage within the physical framework of vehicles. This article delves into the pioneering research led by scientists at Shanghai University, who have explored the potential of 3D printing to fabricate highly efficient structural batteries tailored for various applications, ranging from personal automobiles to autonomous robots.

Structural batteries represent a transformative approach in the design of energy storage systems. Unlike traditional batteries that are external and often cumbersome, structural batteries are embedded directly into the vehicle’s architecture. This integrated design not only saves space but also enhances the vehicle’s overall structural integrity. Essentially, these batteries must fulfill two critical tasks: they must store energy effectively while also bearing significant loads during operation. The recent strides made by researchers highlight the feasibility of developing such innovative systems that possess high energy densities alongside robust structural characteristics.

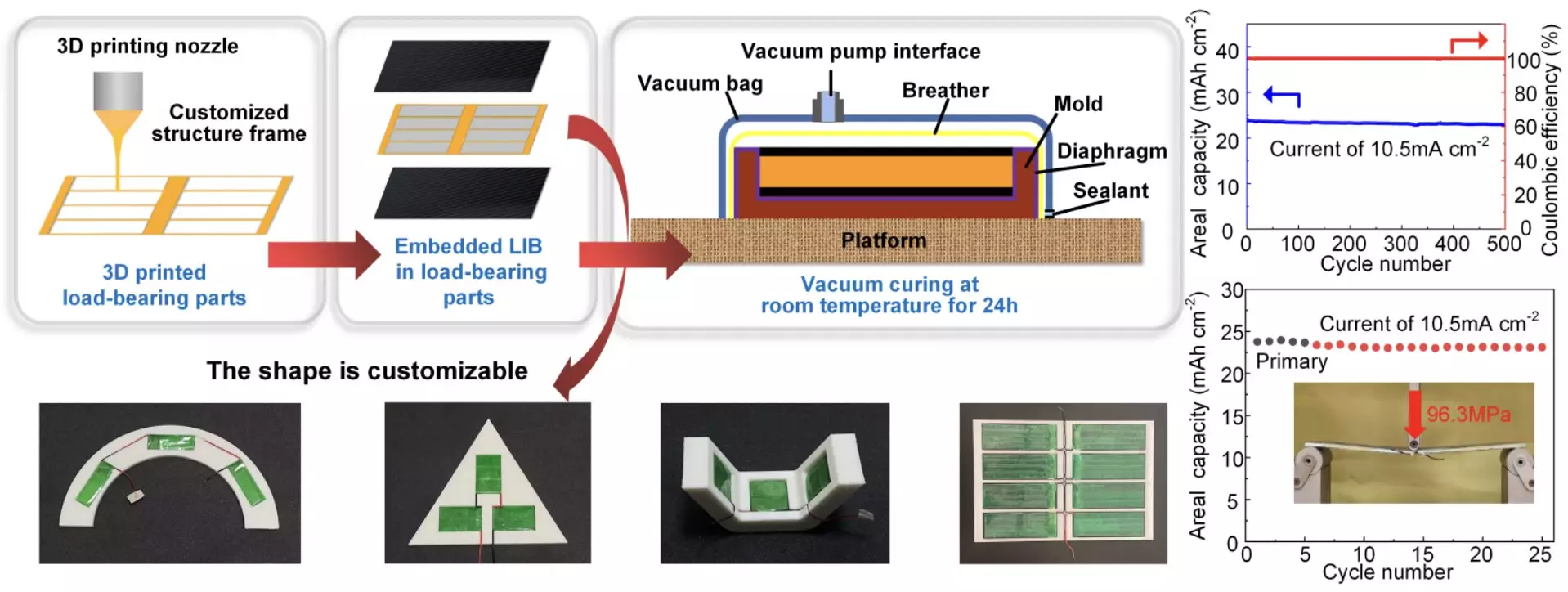

The groundbreaking study published in *Composites Science and Technology* underscores the use of advanced 3D printing techniques in the creation of structural lithium-ion batteries. By utilizing 3D printing, researchers can design customizable geometric shapes that cater to the specific requirements of diverse applications. According to Yinhua Bao, the project’s lead investigator, the objective is to create a composite that combines high energy storage capacity with exceptional load-bearing capabilities. This adaptable fabrication process enables tailored solutions for different needs, significantly enhancing the applicability of structural batteries across various sectors.

The introduction of a decoupled structure is crucial in mitigating the physical stress placed on the energy storage materials. Such designs help ensure that the structural framework predominantly absorbs external loads, thereby protecting the reactive components of the battery from mechanical damage. The research team’s innovative framework thus positions itself not only as a means to improve performance but also to prolong battery life by minimizing wear and tear.

The performance metrics achieved by the newly fabricated structural batteries are nothing short of impressive. Initial experimental results indicate a remarkable energy density of 120 Wh/kg and 210 Wh/L at operational currents of 3.5 mA/cm². Furthermore, in rigorous stress testing scenarios, the structural batteries maintained a staggering 92% of their energy capacity even after 500 cycles, demonstrating their potential for longevity and reliability in real-world applications. This is particularly significant as it suggests that the batteries can endure both tensile and bending stresses without substantial degradation.

Bao further noted the distributed arrangement of battery cells, which not only prevents localized failures but also enhances the overall robustness of the energy storage unit. This innovative design promotes a balance between energy density and mechanical performance, thereby presenting an appealing solution for next-generation energy storage needs.

While the immediate applications for structural batteries likely center around electric vehicles, the potential for expansion into other areas is vast. The versatility of the manufacturing process allows these batteries to be tailored for various types of autonomous systems, including drones and logistics robots. As research continues, the team foresees a future where structural batteries could play a pivotal role in reshaping capacities for energy-sustainable vehicles and automated technology.

Moreover, the implications of this technology extend beyond just vehicular applications; it can revolutionize energy storage strategies in other fields such as consumer electronics, aerospace, and industrial automation. The ability to integrate structural batteries into the design of components opens avenues for significant weight and space savings across a range of technologies.

The research conducted by Bao and his colleagues signifies a monumental leap forward in energy storage technology. The innovative use of 3D printing to create structural batteries not only addresses existing limitations in energy density and durability but also paves the way for broader adoption in various applications. As this field develops, it holds the promise to redefine energy systems in vehicles and beyond, ultimately contributing to a more efficient and sustainable future. Future work is anticipated to explore the deployment of these batteries in unmanned aerial vehicles and robotic systems, marking just the beginning of what is possible with structural battery technology.

Leave a Reply