Ultra-high-performance concrete (UHPC) is gaining traction in the field of construction due to its remarkable strength and durability compared to traditional concrete materials. With the increasing complexity of modern architectural designs and demands for enhanced structural integrity, UHPC has emerged as a go-to solution for engineers and constructors. However, the challenge of fully understanding its compressive characteristics, particularly when enhanced through the use of fiber-reinforced polymers (FRP), has remained largely unresolved. A recent study published in the field of engineering is set to change this narrative by developing a stress–strain model that significantly improves the analysis of FRP-confined UHPC.

Conducted by a team of researchers from Huazhong University of Science and Technology and Southern University of Science and Technology, this study seeks to fill a crucial gap in structural engineering models currently available. While existing models have proven effective for normal-strength concrete (NSC) confined by FRP, they fail to adequately represent the unique behavior of UHPC under similar conditions. This limitation has implications for engineers aiming to design safe and durable structures with UHPC, as it restricts their understanding of how external constraints can affect internal concrete behavior.

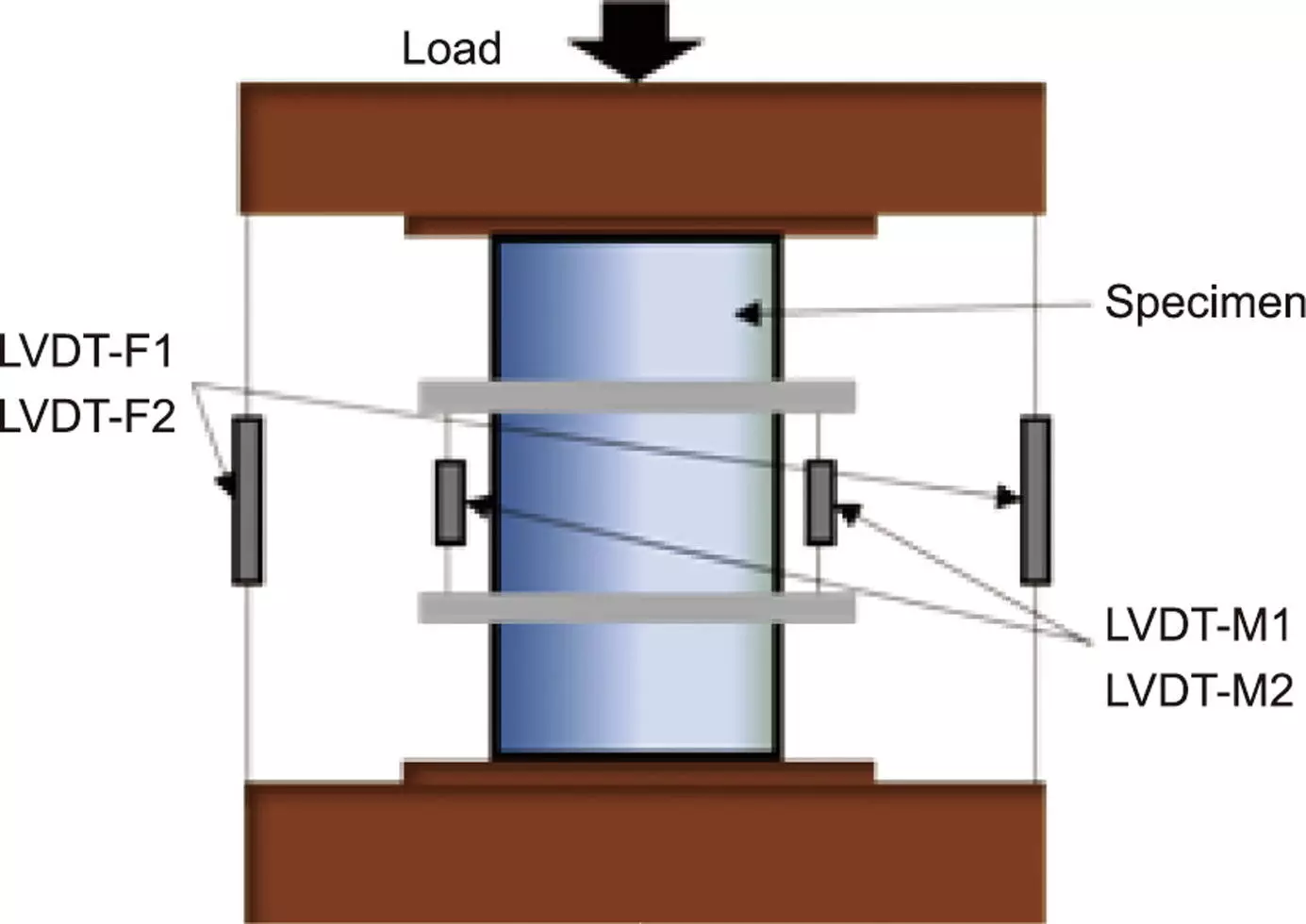

The research team, led by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie, undertook a series of experimental tests to scrutinize UHPC’s performance while subjected to concentric compression with FRP encasement. Their findings challenge previously accepted assumptions and highlight the necessity for a more sophisticated analytical approach.

One of the principal revelations from the researchers’ investigations is the inadequacy of the stress-path-independency assumption. While this principle holds when evaluating NSC—suggesting that the behavior of concrete under varying stress paths does not deviate from expected patterns—UHPC exhibits significant deviations. Major diagonal cracking and subsequent non-uniform lateral expansion mark a pivotal difference; these occurrences diminish effective confining pressure and disrupt the expected behavioral consistency tied to stress pathways.

This insight necessitated a reevaluation of existing models, leading to the development of a new analytical framework that incorporates the critical influence of stress-path dependency. This innovation not only pushes the boundaries of current knowledge but also enables the prediction of UHPC behavior under more realistic conditions.

The researchers constructed a new model encompassing adjustments that consider the dynamics of confining pressure as well as a newly introduced equation to address the confining pressure gap. Rigorous testing with a robust database of experimental results confirmed the validity of the new approach. Compared to its predecessors, the new model exhibited notable accuracy in predicting the stress–strain behavior of FRP-confined UHPC.

This systematic advancement is not merely technical; it signifies a paradigm shift in how engineers and researchers can approach high-performance concrete applications. By bridging the understanding of UHPC’s mechanical properties in real-world scenarios, this model serves to enhance both design accuracy and structural safety.

The ramifications of this study extend far beyond theoretical advancements in material science. The ability to accurately predict the behavior of FRP-confined UHPC equips engineers with the tools to foster safer and more reliable designs in construction. It enables a more informed approach to UHPC applications, presenting opportunities for optimizing both efficiency and durability in structural projects.

This breakthrough paves the way for future research endeavors focused on UHPC and its composite materials. The insights gleaned from this study are poised to influence widespread changes in design standards, regulations, and methodologies across the construction landscape. Researchers and practitioners alike will benefit from this analytical model, driving innovation in concrete technology and redefining standards of excellence in structural engineering.

The introduction of a refined stress–strain model for FRP-confined UHPC represents an important milestone in concrete sciences. As the construction industry evolves and seeks alternatives that promise longevity and resilience, this research offers vital foundations for safer structural designs. The implications are clear: improved understanding of UHPC behavior will catalyze advancements in construction practices, ultimately leading to structures that not only stand the test of time but also meet the rigorous demands of modern engineering challenges.

Leave a Reply