The textile industry has long been criticized for its significant contribution to environmental degradation. Millions of tons of clothing end up in landfills annually, with the average American discarding around 80 to 100 pounds of textiles each year. This alarming statistic underscores the urgent need for innovative solutions to reduce waste and shift toward more sustainable practices. Recent advancements in eco-friendly waterproof coatings, developed by researchers at Cornell University, signal a promising direction for the future of textile manufacturing. This initiative not only aims to tackle waste management but also seeks to mitigate the adverse effects associated with traditional waterproofing materials, which often contain harmful chemicals.

Under the guidance of Juan Hinestroza, a respected professor in the College of Human Ecology, a research team has devised a novel technique for creating waterproof coatings using discarded textiles. The brilliance of this approach lies in its simplicity and efficacy. By employing metal-organic frameworks (MOFs), which can be synthesized using environmentally friendly solvents—specifically water and ethanol—the researchers have managed to create superhydrophobic coatings without the need for energy-intensive processes like separation or purification. This game-changing method not only preserves resources but also minimizes the use of hazardous substances traditionally employed in textile coatings.

Yelin Ko, a doctoral student leading the charge in this research, is at the forefront of this innovative project. Their paper, “UiO-66 Inspired Superhydrophobic Coatings Fabricated from Discarded Polyester/Spandex Textiles,” showcases the results, demonstrating the potential for transformative changes within the industry. The integration of discarded polyester and spandex materials further enhances the innovation of this initiative, emphasizing the need for a circular economy in fashion.

At the heart of this research is the low-temperature synthesis process, which not only reduces energy consumption but also offers a sustainable alternative to traditional chemical synthesis methods. By chemically decomposing discarded fabrics through an alkaline depolymerization process, the researchers isolate necessary components, such as disodium terephthalate—a recognized linker for synthesizing UiO-66, a well-regarded MOF.

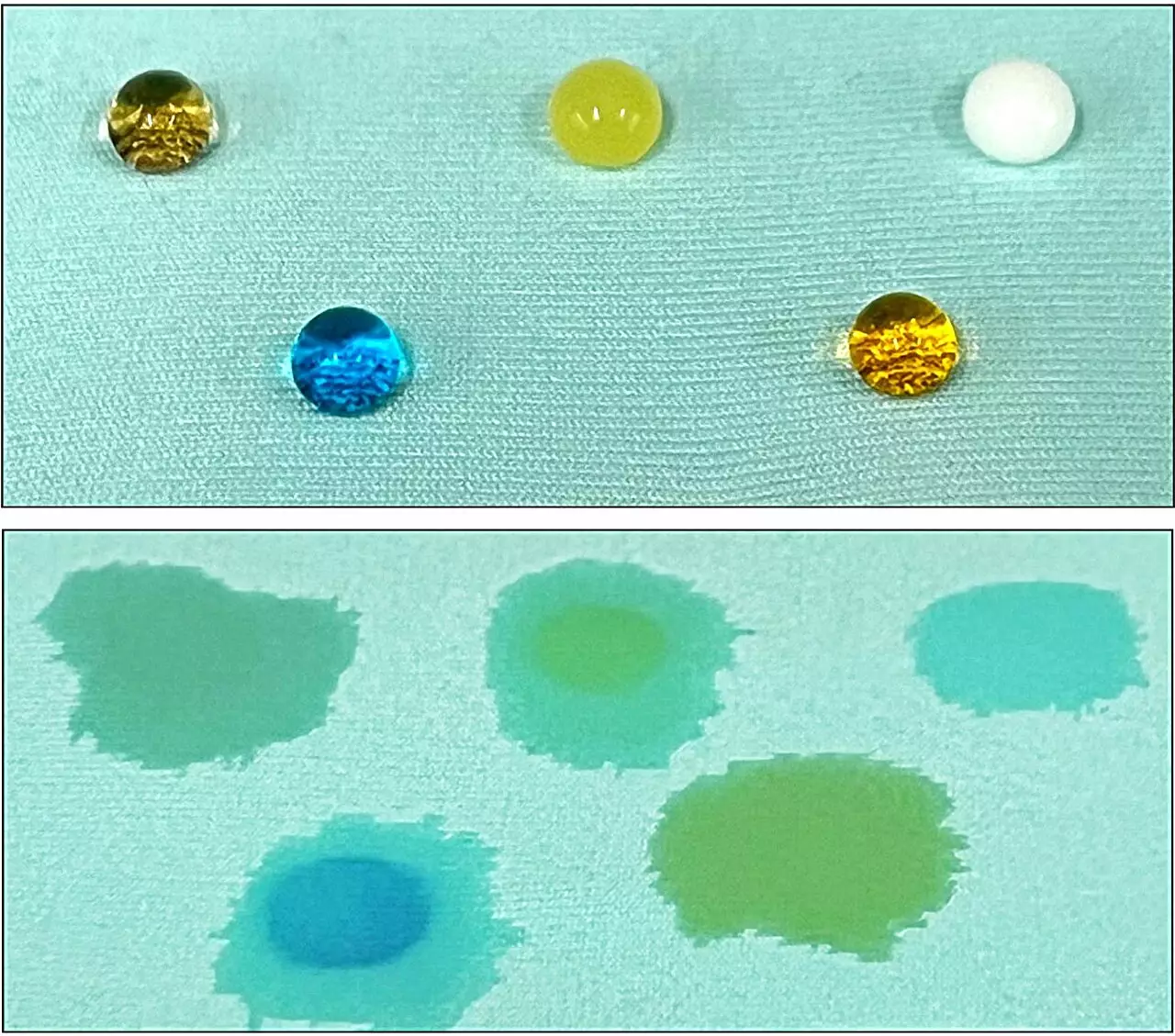

Their findings revealed that by adjusting the quantity of ethanol used during the synthesis, the UiO-66 structure effectively adhered to polyester and spandex substrates, resulting in an impressive superhydrophobic effect. Interestingly, the spandex fragments played a critical role in modifying the MOF’s hydrophilic properties, contributing to its newfound water-repelling abilities.

One of the key outcomes of this research is the durability of the coatings. The UiO-66 material showcased remarkable resilience, maintaining its waterproof properties even after undergoing multiple wash cycles and abrasion tests. This durability is crucial for consumer acceptance, as the functionality of coated textiles must withstand the rigors of daily wear and laundering.

Furthermore, the potential for these coatings extends beyond mere waterproofing; they hold promise for a variety of applications, including fire resistance and antibacterial properties. By tapping into the capabilities of MOFs, Hinestroza and his team open a door to reimagining the functionalities of textiles while simultaneously addressing pressing environmental concerns.

As the research team emphasizes, the upcycling aspect of their work is arguably the most significant. Moving towards sustainable practices requires a collective effort from consumers, manufacturers, and brands alike. Hinestroza articulates the importance of consumer behavior, suggesting that the onus is on individuals to reduce their reliance on fast fashion and the disposable culture that has led to excessive waste in the textile industry.

This shift in mindset is essential for the success of innovative solutions. The introduction of non-toxic, environmentally friendly waterproof coatings not only alters production practices but also empowers consumers to make more informed, sustainable choices. By prioritizing eco-conscious alternatives, the industry can gradually reduce its dependence on harmful chemicals, including so-called “forever chemicals” that linger in the environment.

Cornell University’s innovative approach to creating waterproof coatings through textile upcycling heralds a new chapter in sustainable fashion. By focusing on reducing waste and utilizing environmentally sound materials, researchers have set a compelling precedent for the industry. However, real change will only materialize through a collaborative effort from all stakeholders involved. By fostering a culture of sustainability rooted in responsible consumption and innovative manufacturing practices, we can collectively progress toward a more eco-friendly future in the textile realm and beyond.

Leave a Reply