In an age where sustainable energy solutions are more critical than ever, the exploration of sodium-ion batteries (SIBs) has emerged as a promising avenue. Researchers have unveiled a groundbreaking process technology that dramatically reduces the time required to prepare hard carbon anodes for these batteries from hours to a mere 30 seconds. This innovation hinges on the use of microwave induction heating, a technique that has been readily accessible for food preparation in our kitchens.

The Sodium-Ion Battery: A Viable Alternative

Sodium-ion batteries represent a next-generation option in the battery landscape, utilizing sodium (Na) instead of lithium (Li). Sodium, abundant and easy to extract, is over a thousand times more prevalent than lithium, making it an attractive material for future battery technologies. Its lower reactivity when compared to lithium translates into enhanced electrochemical stability. This stability is especially beneficial for applications requiring rapid charge and discharge cycles, such as electric vehicles and renewable energy storage solutions. Furthermore, sodium-ion batteries are expected to perform better in cold temperatures, addressing a significant limitation of conventional lithium-ion batteries.

However, several hurdles must be overcome for SIB technology to realize its full potential. These include comparatively lower energy density and reduced lifespan when measured against their lithium-based counterparts. Importantly, the manufacturing intricacies associated with creating the required hard carbon anodes present significant challenges. The larger size of sodium ions necessitates a specialized form of carbon—hard carbon—characterized by interlayer spacing that exceeds that of graphite, the standard material for current anodes.

The traditional method for fabricating hard carbon involves a complex and lengthy carbonization process, requiring the heating of hydrocarbon materials in an oxygen-free environment at extreme temperatures, often exceeding 1,000 degrees Celsius. This method is not only economically taxing but environmentally wasteful, contributing to the difficulties in scaling up sodium-ion battery production to meet commercial demands.

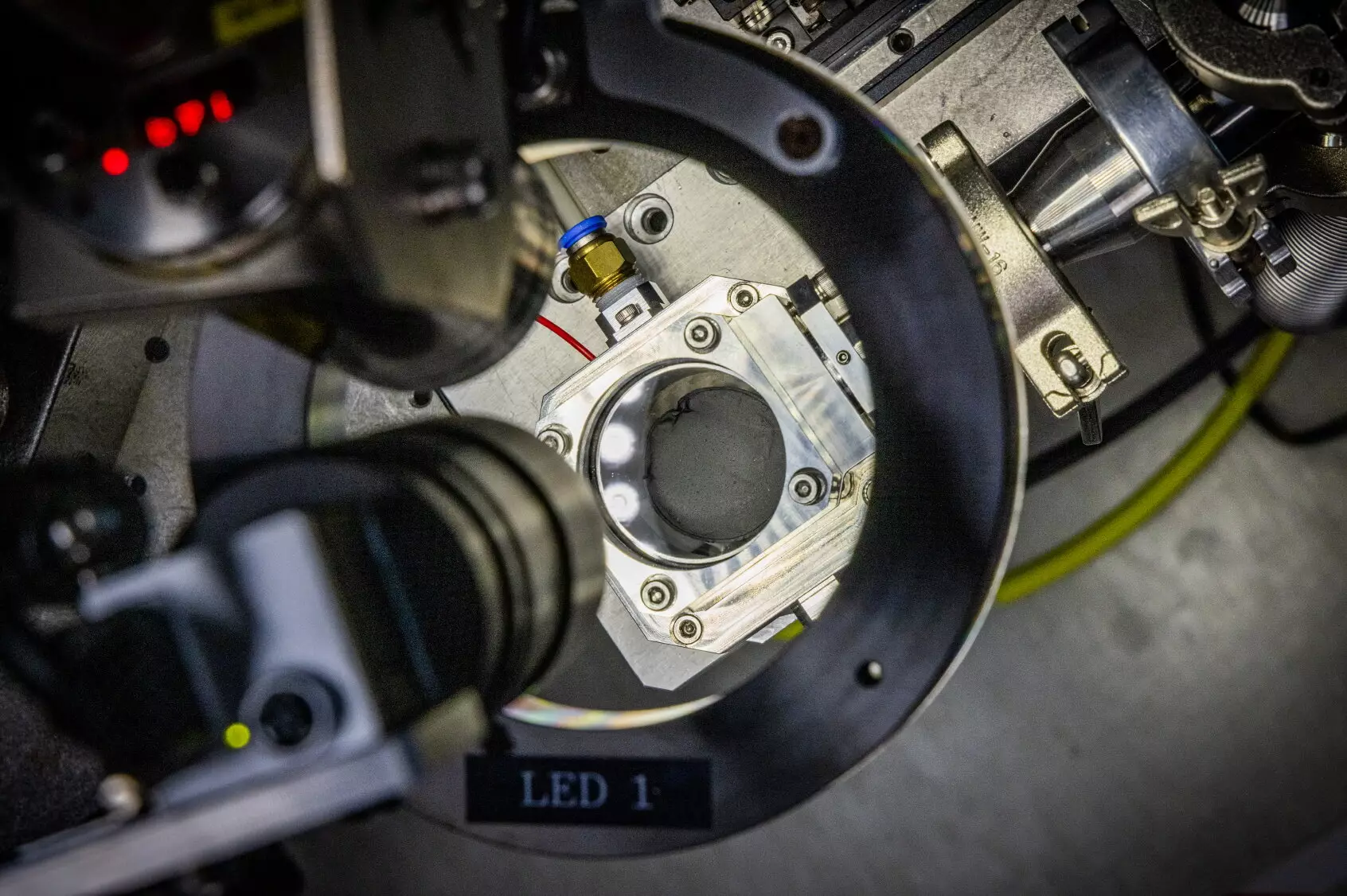

It is within this context of challenges and opportunities that the research team led by Dr. Daeho Kim and Dr. Jong Hwan Park asserts its influence. Their innovative application of microwave technology has been pivotal in rethinking battery anode material preparation. By integrating highly conductive carbon nanotubes with polymers to create composite films, they have harnessed microwave magnetic fields to selectively heat these products to over 1,400 degrees Celsius in just half a minute.

Technological Breakthroughs and Their Implications

The pivotal innovation lies in the recent advancements made by the Korea Electrotechnology Research Institute (KERI) in the realm of microwave heating technology. This technology facilitates uniform heat treatment of conductive materials, providing a tantalizing glimpse into the future of efficient and rapid battery material synthesis. The study detailing these findings was co-authored by emerging researchers Geongbeom Ryoo and Jiwon Shin, who gained experience through KERI’s collaborative research initiatives.

As Dr. Jong Hwan Park notes, the relevance of this innovation correlates closely with the rising safety concerns surrounding electric vehicles, citing recent incidents of battery fires. The search for safer battery technologies has accelerated industry interest in SIBs, particularly as potential solutions for lower energy efficiency and production costs of conventional anodes persist.

Dr. Daeho Kim emphasizes the promise of the newly developed microwave induction heating process, asserting its potential to simplify and expedite hard carbon production. This breakthrough lays a foundational stone for the broader commercialization of sodium-ion batteries.

Looking ahead, the research team remains committed to enhancing the performance of their anode materials while devising methods for the continuous mass production of large-area hard carbon films. The microwave induction heating technique could extend its impact beyond sodium-ion batteries, potentially facilitating advancements in all-solid-state batteries, which demand high-temperature sintering processes.

KERI’s accomplishments have been formalized with a domestic patent application, signaling the institution’s anticipation of heightened interest from industry players within the energy storage sector. The comprehensive implications of this technology could foster collaborations and technology transfer agreements as companies seek to innovate in an increasingly competitive marketplace.

The integration of microwave induction heating into the preparation of sodium-ion battery anodes represents a landmark achievement, not only advancing battery technology but also aligning with global trends towards sustainable energy solutions. As the landscape evolves, the coordinated efforts of dedicated researchers like Dr. Kim and Dr. Park will shape the future of energy storage, moving steadily towards a cleaner and more efficient world.

Leave a Reply