The advent of nanotechnology has heralded a new era in scientific innovation, merging the roles of engineering, materials science, and molecular chemistry. At the forefront of this revolution are molecular machines, showcasing intricate functionalities at the nanoscale that could fundamentally alter various sectors, from data storage to biomedical applications. A significant leap in this domain has been reported by a pioneering research team at the Ulsan National Institute of Science and Technology (UNIST) in South Korea. Directed by the visionary Professor Wonyoung Choe, this groundbreaking study demonstrates how zeolitic imidazolate frameworks (ZIFs) can transcend traditional limitations, providing a model for sophisticated mechanical systems at the molecular level.

Engineering with Precision

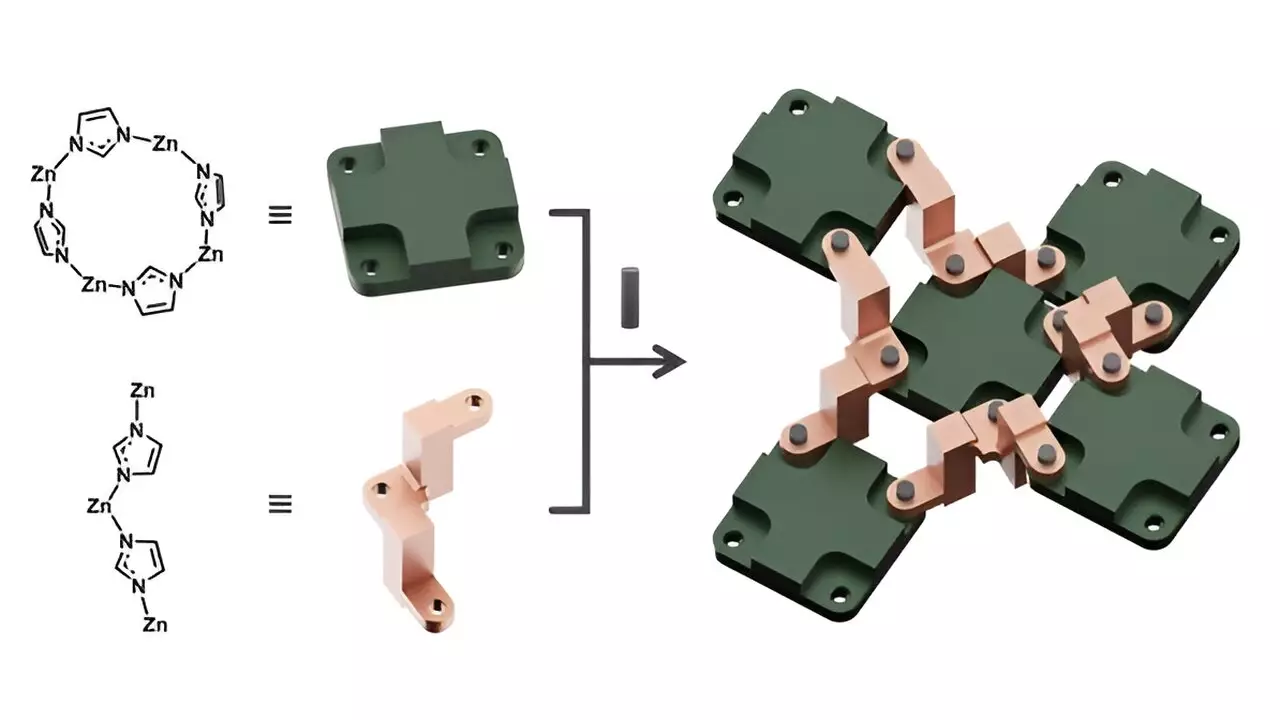

The engineering of molecular machines has traditionally been fraught with challenges, particularly regarding the integration of mechanical properties within solid-state structures. The UNIST team tackled this issue head-on by innovatively integrating metal-organic frameworks (MOFs) with molecular machines, creating a hybrid that exhibits remarkable control over nanoscale mechanical movements. By embedding dynamic components in a MOF as pillared ligands, they capitalized on the inherent stability of these frameworks while introducing functionality typically observed in larger mechanical systems. The result? A molecular machine that is not only operational but also remarkably responsive to environmental stimuli, such as temperature and solvent composition.

A Technological Paradigm Shift

This research marks a pivotal evolution in our understanding of molecular mobility. Unlike conventional materials, the ZIF structures developed can perform complex movements akin to traditional mechanical systems, with the added advantage of being engineered at a molecular level. The unique sliding and cranking motions facilitated by the ZIFs are made possible through precision structure linkage, a rarity in previous studies involving MOFs. The ability to oscillate between rotational and linear movements presents untold possibilities for engineering applications and material design, particularly in fields seeking next-gen storage solutions that are both compact and efficient.

Elasticity: The Game Changer

One standout feature of the UNIST ZIFs is their impressive elasticity and flexibility, surpassing those found in previous materials. This characteristic is essential for the assembly of components requiring precise movements—a key component for future nanomaterials. As Professor Choe stated, the deliberate designs of these mechanical linkages can lead to groundbreaking innovations, potentially redefining how we conceive and produce materials with multifunctional properties. The implications extend beyond traditional realms, encouraging exploratory studies into new engineered substances that can adapt to various applications based on their mechanical attributes.

Opening Doors to Innovation

The work conducted by UNIST not only sets a precedent for the development of multifunctional nanomaterials but also paves the way for future research in the field. The findings spark a compelling dialogue about the intersections of organic chemistry, materials science, and engineering. As scientists continue to decode the principles underlying molecular mechanics, we are poised to witness a new generation of technologies that leverage these innovative ZIFs. The potential to create materials tailored to specific tasks, whether in medicine, electronics, or environmental science, illustrates the necessity of nurturing this research to unlock the full power of molecular machines.

Leave a Reply