In a world increasingly driven by technology, the importance of advanced materials cannot be overstated. Engineers and researchers are constantly on the hunt for new substances that can withstand extreme conditions while being lighter and stronger than their predecessors. A groundbreaking microscopy method has emerged, promising to accelerate the development of superior materials such as high-performance alloys and custom semiconductors. The research published in *Nature Materials* highlights a phenomenal leap in our understanding of the atomic architecture of crystalline materials—an understanding that could redefine industries, from aerospace to electronics.

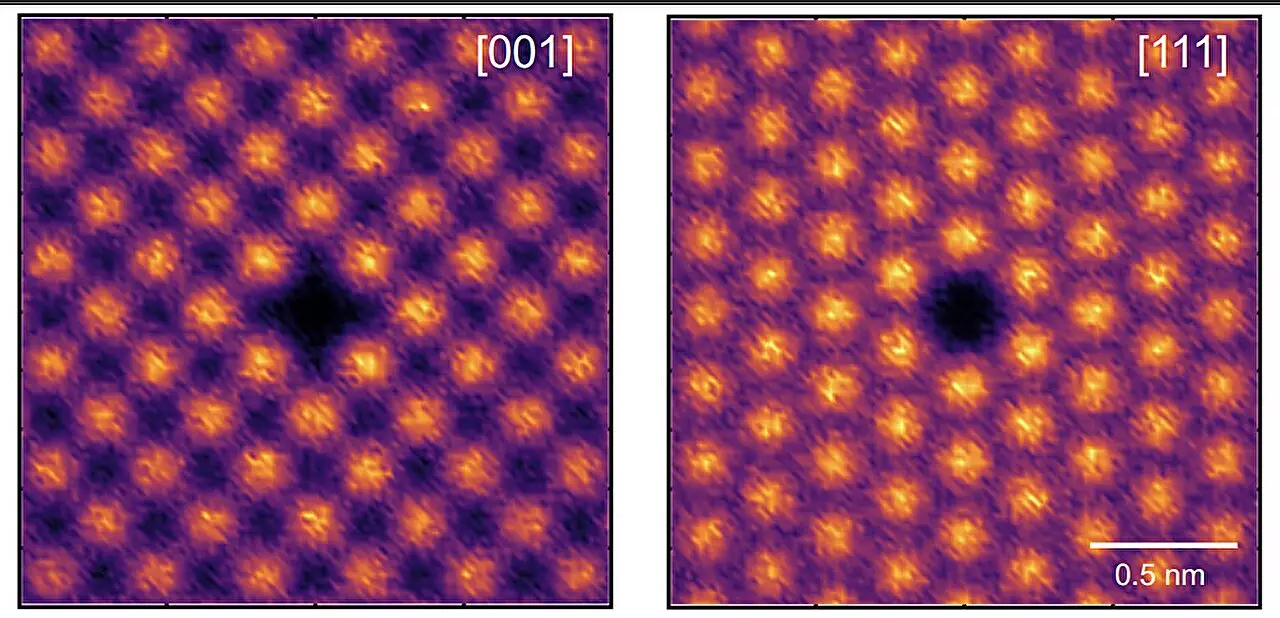

This new approach, championed by a team from the University of Sydney, leverages the groundbreaking technique known as atom probe tomography (APT). This innovative tool allows scientists to visualize and quantify the intricate atomic arrangements in crystalline structures. It is not merely a technical advancement; it establishes a new framework for examining the similarities and differences in materials previously deemed too complex for conventional microscopy. By focusing on short-range order (SRO)—the immediate atomic environment that governs material behavior—researchers are carving a path toward developing materials tailored for specific applications.

Understanding the Intricacies of Short-Range Order

Short-range order plays a crucial role in determining how materials behave under varying conditions. Until recently, investigating these atomic-level interactions has proven to be a daunting challenge, as the requisite spatial resolutions were simply beyond the reach of traditional methodologies. The significance of SRO can be likened to understanding the ‘genome’ of materials—the arrangement of atoms that dictates their electronic, magnetic, and mechanical properties. This insight is especially valuable for industries requiring high-performance materials that can function under extreme conditions.

The research headed by Professor Simon Ringer goes beyond just determining the elemental composition of materials. Instead, it probes the nuanced relationships between atoms, asking whether these spatial configurations are random or exhibit a certain level of order. “Utilizing SRO data enables us to unlock new potentials for custom-designed materials where properties like strength are paramount,” he asserts. This is a compelling prospect, as material design can be approached almost like engineering a chemical formula—atom-by-atom—resulting in advanced materials that closely align with the demands of modern technology.

Implications for Advanced Engineering Applications

High entropy alloys (HEAs) represent a fascinating domain of study within this research. These complex alloys are made by mixing several principal elements, providing potentially high strength and stability at both elevated temperatures and in radiation-rich environments. The wide-ranging applications of HEAs—encompassing everything from jet engines to nuclear reactors—underscore their importance. Professor Ringer observes, “Given that many industries are focused on high-temperature and high-stress conditions, this research could ultimately affect how safety and functionality are approached across various sectors.”

Using APT, the research team meticulously investigated the local atomic environments of a cobalt-chromium-nickel high entropy alloy. They were able to discern how different heat treatments influenced the SRO, providing crucial data that could revolutionize how materials are engineered. This methodology paves the way for new practices in material science, allowing for more predictive capabilities when it comes to modeling how materials will behave under different processing techniques.

Empowering Researchers with New Insights

The significance of this work extends into the realm of computational simulations as well. Dr. Mengwei He emphasizes, “Understanding SRO equips us with the tools to transform material design methodologies, leading to breakthroughs in how we approach materials with great potential.” By establishing a detailed blueprint of atomic arrangements, researchers are granted unprecedented insight into the microscopic factors affecting material properties.

The implications of this study stretch far beyond basic research. By facilitating data-driven simulations and offering practical applications, this advancement could significantly lower production costs while enhancing the performance of a myriad of devices and structures. The rigorous sensitivity analysis presented by the research team further solidifies the validity of measuring SRO and its implications for the broader materials community.

A Bright Future for Material Science

The intersection of atom probe tomography and short-range order measurement represents an exhilarating frontier in materials science. This innovative approach enables researchers to not only forge a deeper understanding of materials but also to customize them for specific applications. With the potential to impact numerous high-tech industries, from renewable energy to space exploration, the findings from this research are nothing short of revolutionary. The ability to quantify atomic relationships promises a future where materials can be manufactured with unmatched precision and reliability, serving as pivotal building blocks for next-generation technologies.

Leave a Reply