The advent of “glassy gels” signifies a paradigm shift in the landscape of material science. Imagine a substance that seamlessly blends hardness with remarkable flexibility, akin to the resilience of glass yet capable of stretching multiple times its original length. This breakthrough challenges long-standing dichotomies between rigid glassy polymers and soft, pliable gels, promising a versatile material that can cater to a diverse range of technological and industrial needs. Such constructs open exciting avenues, particularly in fields where durability, flexibility, and conductive properties are paramount, providing a new toolkit for engineers and designers eager to push the boundaries of innovation.

What makes glassy gels particularly compelling is their straightforward manufacturing process, which sidesteps the complexities and costs associated with traditional plastics and glass fabrication. This simplicity heralds fast, scalable production methods—including moldings and 3D printing—making the material accessible for mass adoption. As industry standards evolve, this ease of manufacture could disrupt supply chains, promote sustainable practices, and reduce environmental impact by replacing more energy-intensive materials. It is a noticeable step forward, emphasizing not just the properties of the material itself but also the potential for streamlined, eco-conscious production.

Marrying Contradictions: Hardness Meets Stretchability

Traditionally, materials have fallen on one side of a spectrum—either being hard and brittle like glass or flexible and soft like gels. Glassy gels dismantle this binary by combining the best of both worlds. At the heart of their extraordinary qualities lies their unique molecular composition, which is over 50% liquid yet structured enough to be considered as hard as conventional glassy polymers. This is achieved through a delicate balance of molecular forces; ionic liquids create a specialized environment where polymer chains are kept at bay enough to allow stretching while still being drawn tightly enough to maintain hardness.

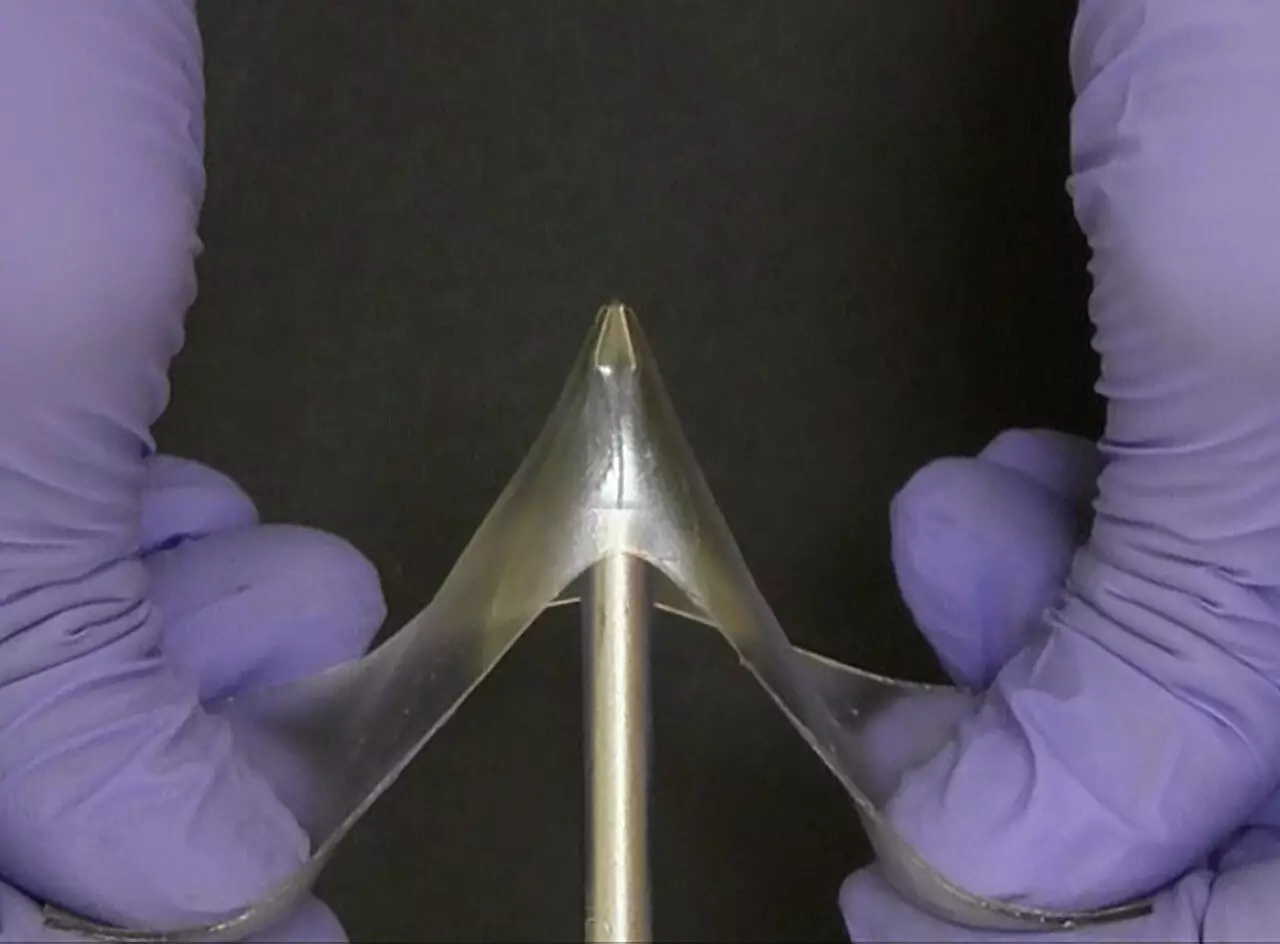

This characteristic defies conventional wisdom. Typically, adding liquids to polymers results in softer, more pliable materials. However, in this case, the ionic liquid acts as a kind of molecular buffer—it pushes polymer chains apart without allowing them to move freely, thus imparting a “glassy” rigidity. The ability to stretch up to five times their original length without breaking, then revert to their initial shape with heat, positions these gels as resilient contenders for applications demanding both flexibility and structural integrity. Moreover, their adhesive surface properties introduce an entirely new dimension—one that could revolutionize fields from medicine to aerospace.

Implications and Potential in a World Demanding Innovation

The implications of such research extend beyond the laboratory, beckoning an era where materials are more adaptable, efficient, and functional than ever before. For instance, in wearable technology, devices made from glassy gels could endure daily wear and tear while maintaining excellent electrical conductivity, even through repeated deformation. Furthermore, their high adhesiveness promises advantages in biomedical fields—think surgical adhesives, wound dressings, or implant interfaces that need to stick securely yet be gentle on tissues.

From a manufacturing perspective, the production process is refreshingly straightforward. Unlike traditional plastics that require complex extrusion or molding processes with substantial energy inputs, glassy gels can be created via simple curing methods. This brings manufacturing closer to rapid prototyping and customization, pivotal for industries that value agility and innovation. In particular, additive manufacturing—such as 3D printing—stands to benefit significantly, enabling designers to craft complex, durable structures on demand. If these materials can be harnessed effectively, they could challenge existing paradigms of material selection, favoring more versatile and sustainable solutions.

Nevertheless, questions remain about the boundaries of their capabilities. While the preliminary research suggests broad polymer applicability and excellent retention of moisture and electrical conduction, the longevity and stability of glassy gels under real-world conditions warrant further scrutiny. Their high adhesion, for one, is a double-edged sword—an advantage in many applications but potentially problematic where removable or non-stick properties are desired. These nuances underscore the need for ongoing research to understand and control their surface interactions.

Transformative Potential with an Open Future

The true power of glassy gels lies not merely in their properties but in their potential to catalyze industry shifts. Their combination of hardness, stretchability, electrical conductivity, and adhesiveness sets the stage for innovations that could redefine product design and functionality. Imagine electronic skins capable of conforming to complex surfaces, or impact-resistant yet flexible devices that can withstand rough handling—these are now within the realm of possibility.

Most compelling is the prospect that this material could democratize advanced manufacturing, allowing more players—small startups, research labs, and even hobbyists—to develop complex, high-performance products without the prohibitive costs typically associated with high-strength materials. As further research elucidates the full scope of their capabilities and limitations, we stand at the threshold of a new era where boundaries between material classes blur, fostering a future that’s more adaptive, resilient, and innovative.

If industry and academia embrace this breakthrough, the landscape of advanced materials could undergo a fundamental transformation—one driven by simplicity, versatility, and a willingness to rethink what is physically possible. The emergence of glassy gels is a testament to human ingenuity and the boundless potential of innovative scientific inquiry to reshape how we build and interact with the material world.

Leave a Reply