Fluidic technologies are integral to numerous sectors, including healthcare, pharmaceuticals, and environmental management. The need for sophisticated methods to capture, control, and release various liquids accurately remains a significant obstacle within these fields. Addressing this challenge, researchers at The Polytechnic University of Hong Kong (PolyU) have developed an innovative solution known as Connected Polyhedral Frames (CPFs). This advancement, spearheaded by Dr. Zhang Yiyuan and led by Prof. Wang Liqiu, promises to transform fluid manipulation with remarkable precision and reliability.

Fluid handling, despite its fundamental importance, is fraught with difficulties. Unlike solid materials, liquids present unique challenges such as wetting and spontaneous spreading, which complicate their transfer and utilization. Conventional tools like pipettes, microtubes, and swabs, while commonly employed, often lead to inter-sample contamination and hinder volumetric accuracy. Furthermore, the disposable nature of these tools significantly contributes to global plastic pollution, making it paramount for researchers to find robust and sustainable alternatives.

The challenge of achieving reversible and controlled fluid transfer is pivotal for many applications. Being able to switch between capturing and releasing fluids with precision affects everything from drug delivery systems in medical applications to chemical processing in industrial settings. Having a system that can manipulate liquids in a programmable and efficient manner can drastically change how various sectors approach fluid dynamics.

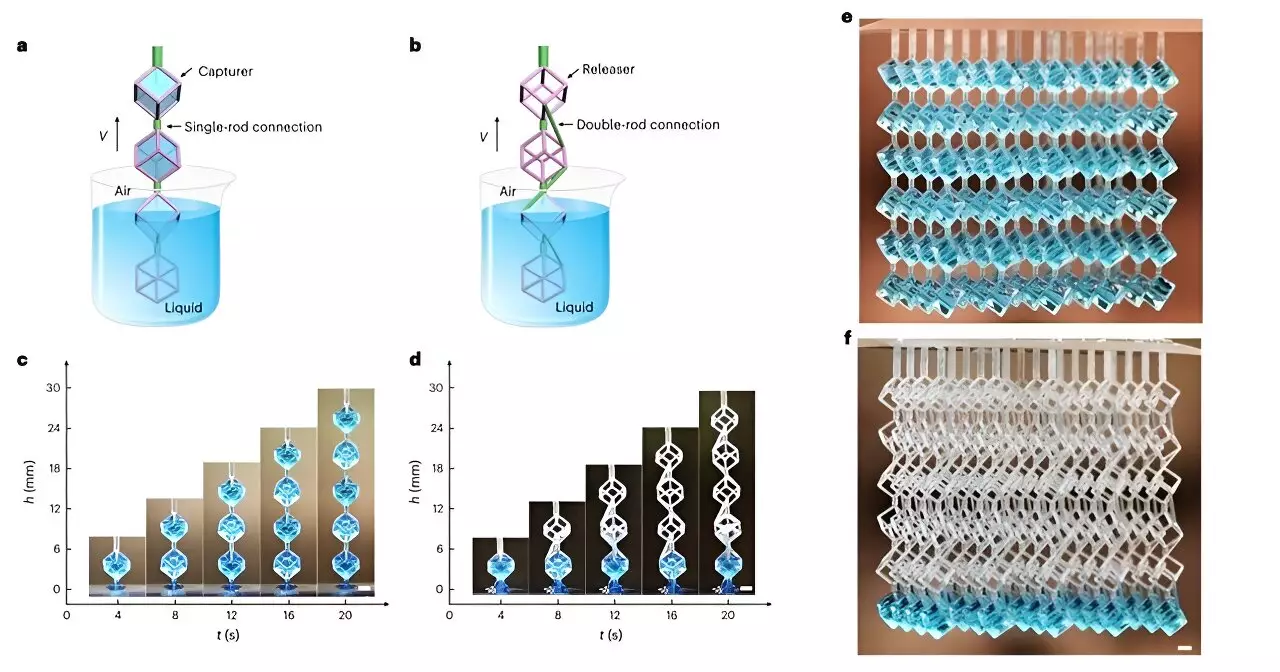

The uniqueness of CPFs lies in their design. Acting as a meta-metamaterial, these frames allow for a seamless transition between capturing and releasing, independent of the liquids being processed. The innovative framework comprises structures that either capture liquids when joined in a single-rod configuration or release them when in a double-rod configuration. This switchable nature ensures that the liquid can be retained or drained dynamically, depending on the requirements of the specific application.

The versatility of CPFs enables them to work with a variety of liquids, including biopharmaceuticals, organic solvents, and hydrogels. This broad compatibility not only enhances their utility across different sectors but also improves the efficiency of liquid processing within each category. As the need for diversified applications continues to grow, CPFs represent a significant leap forward.

To illustrate the practical capabilities of CPFs, the research team demonstrated their use in controlled multidrug release systems. In a test involving vitamins B2 and B12, researchers effectively encapsulated these vitamins in distinct hydrogels, controlling their release rates by adjusting the thickness of the gel membrane. This precise management is critical for pharmacological applications where dosage regulation is paramount.

Moreover, CPFs have shown promise in biological applications, such as the encapsulation of microorganisms like Acetobacterium. Here, the unique design allows for a simplified process to separate bacteria from reaction products, streamlining microbial reactions, and optimizing resource usage. Such capabilities herald a paradigm shift in how bioproducts may be developed in the future.

Beyond medical applications, the implications of CPFs extend into environmental and energy sectors. Preliminary efforts to develop a commercial scale humidifier using CPFs have indicated increased efficiency through higher water storage capacities and reduced water flow requirements. This not only contributes to energy-saving measures but also enhances the effectiveness of gas absorption processes, notably in carbon capture and storage technologies.

The prospect of developing an ideal CO2 cycle process using CPFs presents an exciting avenue for addressing climate change. By innovating methods to capture and reuse emissions more effectively, researchers may play a pivotal role in advancing sustainable energy solutions and reducing the carbon footprint of various industries.

The development of Connected Polyhedral Frames represents a significant step towards overcoming long-standing challenges in fluid handling. By offering precise control, versatility, and enhanced efficiency, these innovative structures could redefine practices across numerous domains. As industries continually seek advanced methods to improve fluid management, CPFs stand out as a groundbreaking solution that not only meets current demands but also adapts to future innovations in technology. Their impact could redefine expectations and set new standards for fluid manipulation. By addressing environmental concerns and enhancing operational capabilities, CPFs may lead the charge in the next industrial paradigm focused on sustainability and efficiency.

Leave a Reply