The quest for sustainable energy solutions is more pressing than ever, with the world striving towards net-zero emissions. Green hydrogen stands out as a particularly promising candidate. Its potential to be produced using renewable energy sources like solar and wind makes it an appealing option for clean energy storage and utilization. The urgency to develop efficient processes for hydrogen production cannot be overstated; it is a crucial step towards realizing the U.S. Department of Energy’s ambitious goal of achieving net-zero carbon dioxide emissions. Recent advancements in electrochemical reactions, particularly those involving water splitting, may hold the key to unlocking this potential.

Electrolysis: The Role of Proton Exchange Membrane Technology

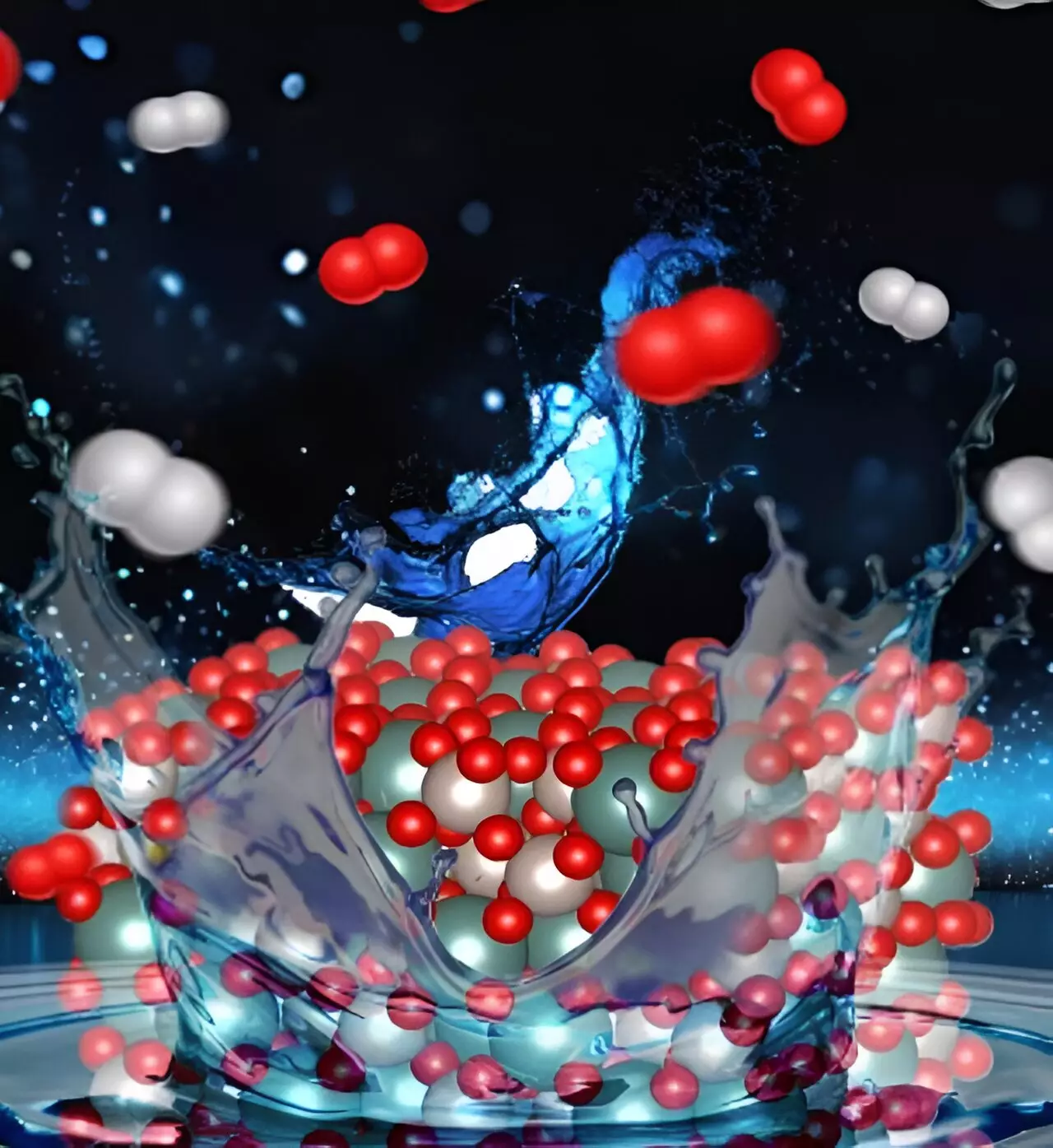

At the heart of green hydrogen production is the process of electrolysis, specifically through proton exchange membrane (PEM) electrolyzers. This technology operates by applying an electrical current to water, effectively splitting it into hydrogen and oxygen. While hydrogen is harvested at the cathode, oxygen is released as a by-product at the anode. However, a fundamental hurdle persists: the production rate of hydrogen is inherently constrained by the slower generation of oxygen. This bottleneck limits the overall efficiency of the electrolysis, emphasizing the need for innovative solutions to enhance both the speed and efficacy of gas production.

Addressing the Bottleneck with Advanced Catalysts

Researchers have now begun to explore advanced catalytic materials to tackle this challenge. A recent study led by Professor Hong Yang from the field of chemical and biomolecular engineering showcased an innovative approach with a new complex oxide catalyst. By leveraging defect engineering techniques, Yang’s team aimed to enhance the catalytic efficiency of electrolysis, thereby improving hydrogen production rates. This cutting-edge catalyst, designed with a pyrochlore mineral structure using ruthenium as a base, has opened new avenues for developing effective electrochemical catalysts.

Defect Engineering: A Game-Changer in Catalysis

At its core, defect engineering involves intentionally introducing imperfections—or defects—into the material at a microscopic level. Contrary to conventional beliefs about material perfection, these strategic imperfections can significantly improve catalytic performance. As Yang points out, this technique parallels practices in the semiconductor industry, where impurities added to silicon to enhance its conductivity. In this context, the team experimented with incorporating trace amounts of yttrium into the ruthenium structure, leading to notable improvements in the rate of oxygen generation.

The research transcends traditional methods, highlighting that the balance between efficiency and the nature of defects is crucial. As graduate student Bidipta Ghosh noted, the findings revealed an unexpected relationship between the oxidation state of the material and its reactivity, even when keeping the concentration of oxygen atoms stable.

Quantifying the Impact of Defect Engineering

One of the standout aspects of this research was the use of thermogravimetric analysis to quantify the creation of oxygen vacancies within the electrocatalysts. This method allowed the researchers to robustly assess how the introduction of yttrium modified the electronic structure of the ruthenium catalyst. The resulting insights provided a blueprint for optimizing the performance of electrochemical reactions. The manipulation of electronic configuration, rather than mere concentration adjustments, proved to be the key lever in boosting the catalytic activity.

The findings reflect a nuanced understanding of how charge distribution and electronic states govern catalytic performance, after all, mere randomization of defects would not yield positive results. Yang’s assertion highlights the need for meticulous control over the type and extent of imperfections in the material composition.

Collaborative Innovation: A Multidisciplinary Approach

A salient feature of this research was the interdisciplinary collaboration that enabled the team to navigate and solve several technical challenges. The synthesis of chemistry, engineering, and materials science facilitated an unique perspective on the project, underscoring how collective expertise can drive significant scientific advancements. As Yang emphasized, the success derived from this diverse collaboration is a testament to the power of teamwork in tackling complex energy challenges.

The innovative applications of defect engineering in catalytic materials for green hydrogen production present a revolutionary opportunity to enhance the efficiency of electrolysis. By understanding the intricate balance between material imperfections and performance, researchers are forging forward toward a sustainable energy future. The implications of these findings suggest a hopeful trajectory for hydrogen as a key player in the transition to a cleaner, carbon-free economy.

Leave a Reply