As society grapples with the adverse effects of fossil fuel consumption—both on the environment and human health—the demand for sustainable energy sources has never been more pressing. Researchers worldwide are committed to identifying alternatives that not only reduce pollution but also replicate the efficiency of traditional fossil fuels. One promising avenue of research lies in the development of biofuels, particularly hydrocarbons known as 1-alkenes, derived from natural resources. A team at the Indian Institute of Science’s Department of Inorganic and Physical Chemistry is at the forefront of this endeavor, and their innovative enzymatic platform may be the game-changer the industry needs.

Enzymatic Platforms: A New Paradigm of Biofuel Production

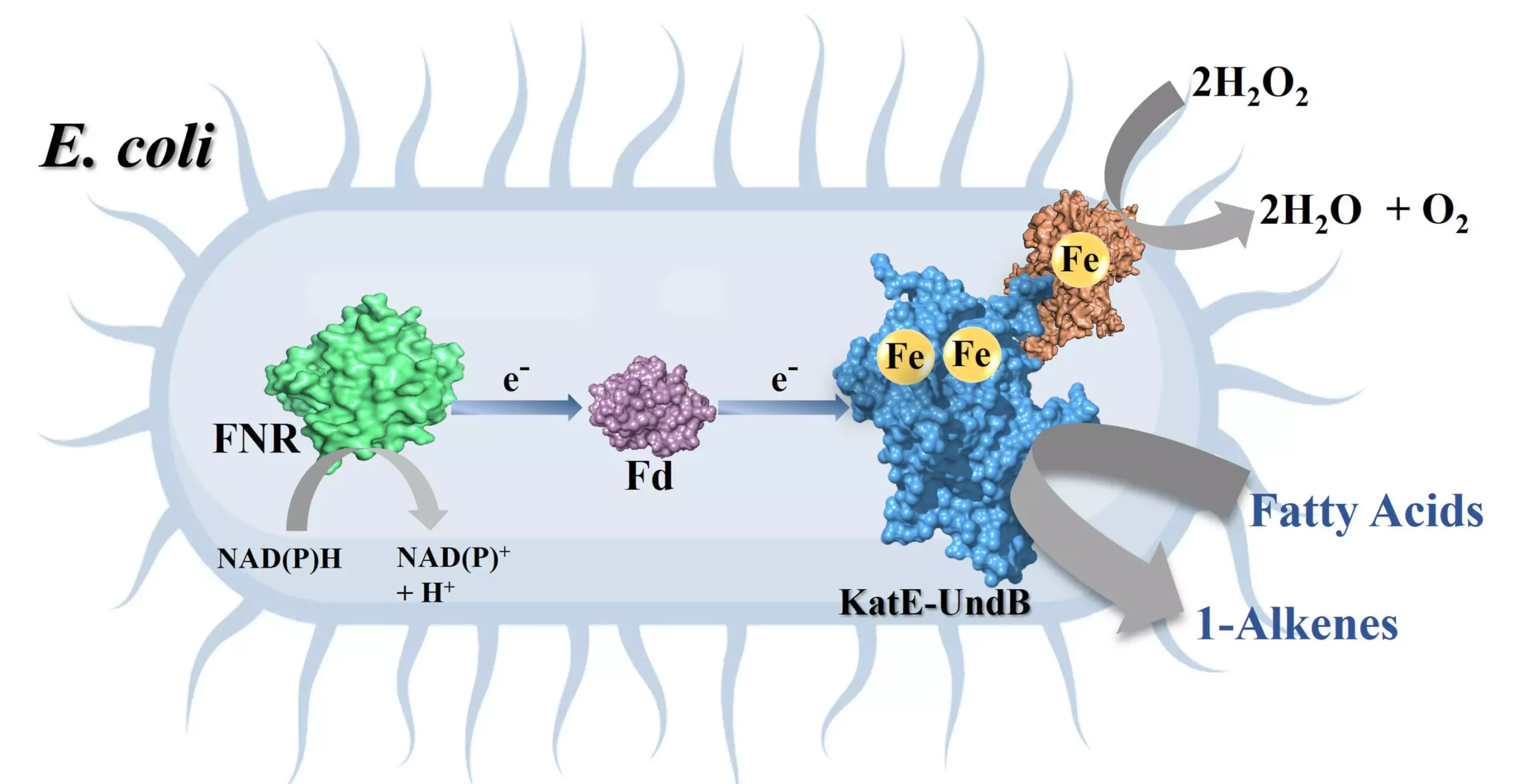

The IISc researchers have unveiled a groundbreaking enzymatic platform capable of transforming abundant and low-cost fatty acids into 1-alkenes, which serve as a viable alternative to conventional fuels. Unlike traditional biofuels that may require extensive processing or present compatibility issues, these hydrocarbons can seamlessly blend with existing fuels and infrastructures, making them “drop-in” alternatives. By harnessing the biology of microorganisms, such as specially engineered E. coli, this platform seeks to establish efficient mass-production capabilities of these sustainable fuels.

Once an intricate part of the research was the enzyme UndB, a remarkable catalyst that binds to cell membranes. In earlier studies, while it was recognized for its rapid conversion abilities, researchers faced a critical hurdle: the enzyme’s susceptibility to inactivation due to hydrogen peroxide (H2O2), a byproduct of the reaction. This challenge impeded the efficiency of the biofuel production process and demanded a scientific rethink to enhance UndB’s operational longevity.

Innovative Solutions: The Role of Catalase

Through their tenacity and critical reasoning, the IISc team identified catalase as a solution to counteract H2O2’s detrimental effects. This enzyme degrades hydrogen peroxide, thereby boosting UndB’s activity significantly—19-fold, to be precise. This leap forward represents a pivotal moment in biocatalysis, as it demonstrates how thoughtful integration of additional biotechnology can lead to tangible efficiency gains in bioprocessing.

The researchers then took a bold step by developing an artificial fusion protein that combines UndB and catalase, effectively creating a chimeric protein designed to enhance overall efficacy. Therein arises the strength of their approach; by engineering genetic codes and introducing them into E. coli, they designed a whole-cell biocatalyst that can sustainably produce 1-alkenes from fatty acids on a large scale.

Challenges and Triumphs in Engineering Biocatalysts

Despite the promising advancements, the research journey was fraught with difficulties. The membrane-bound nature of UndB made it particularly challenging to handle. The team faced issues related to the enzyme’s toxicity to bacterial cells at higher concentrations and its insolubility in water—both significant roadblocks in their experimentation. What’s commendable is the creative problem-solving that unfolded. They explored various redox partner proteins to effectively shuttle electrons to UndB during the conversion process, ultimately determining that proteins such as ferredoxin and ferredoxin reductase, combined with NADPH, played crucial roles in achieving optimal electron transfer efficiency.

This adaptability in their methods underscores the innovative spirit driving the research. The successful incorporation of these partners allowed the biocatalyst to achieve an astonishing 95% efficiency in transforming fatty acids into pure 1-alkenes, a critical attribute given the market demand for clean and efficient fuels.

Future Prospects: A Greener Tomorrow

With their findings validated and a patent for their engineered protein already in the works, the IISc team is poised to make waves in the biotechnology and polymer industries. The uniqueness of their biocatalyst is not only in its efficiency but also in its ability to ensure that the only product generated is 1-alkene, thereby eliminating unwanted byproducts that typically plague chemical production. This level of specificity makes it an alluring option for industries ranging from biofuels to polymers.

As the team seeks to collaborate with industry partners for mass production, there is a palpable excitement about the possibility of reshaping the energy landscape. Successfully scaling this platform could result in a significant reduction in reliance on fossil fuels, propelling society towards a more sustainable future, harnessing the power of biology and chemistry to meet tomorrow’s energy needs.

Leave a Reply