As the world grapples with the repercussions of climate change and environmental degradation, the demand for sustainable solutions has reached an all-time high. In the quest for greener technologies, researchers have unveiled a pioneering battery system that eliminates harmful components traditionally associated with lithium-ion batteries. This promising advancement takes the form of a new fluorine-free binder and electrolyte, designed to enhance both the performance and sustainability of battery technology.

The existing landscape of lithium-ion batteries largely depends on fluorinated compounds, specifically polyvinylidene fluoride (PVDF) and lithium hexafluorophosphate (LiPF6). While these materials have dominated battery technology for years, they pose significant environmental hazards. The release of toxic byproducts, such as hydrogen fluoride (HF), not only jeopardizes battery integrity but also raises grave concerns regarding safety and ecological impact. As regulations concerning per- and polyfluoroalkyl substances (PFAS) tighten, especially within the European Union anticipating a 2026 ban, the research community has a pressing responsibility to innovate environmentally compliant alternatives.

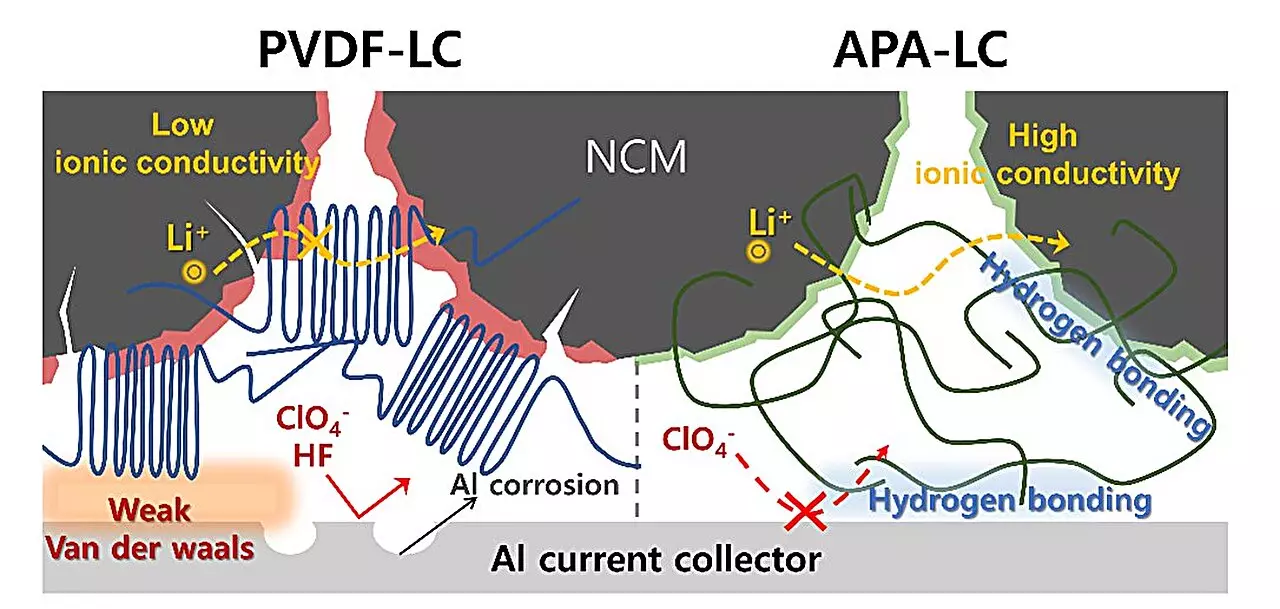

In response to the growing ecological constraints, a research initiative led by POSTECH and Hansol Chemical has given rise to an entirely new battery paradigm. Their investigation resulted in the formulation of a non-fluorinated battery system that comprises a lithium perchlorate (LiClO4) electrolyte and a non-fluorinated aromatic polyamide (APA) binder. Together, this “APA-LC” system sets itself apart by completely forgoing harmful fluorinated materials, marking a significant milestone in sustainable battery development.

The APA binder plays a crucial role in ensuring robust adhesion between the active components of the cathode and the aluminum current collector. By mitigating corrosion risks prevalent in conventional electrolyte systems, this innovative binder can vastly prolong the operational lifespan of the battery. Moreover, the LiClO4-based electrolyte is equipped with added lithium chloride (LiCl) and lithium oxide (Li2O), which facilitate ion transfer at the battery’s interface. The result is a remarkably enhanced ion migration and an impressive performance upgrade when compared to traditional lithium hexafluorophosphate systems.

The efficacy of the APA-LC system has been rigorously tested, yielding promising results. In a controlled environment, the new system demonstrated an oxidation stability far superior to that of the widely used PVDF-LP configuration. After 200 cycles at a rapid charge/discharge rate of 1 C, the APA-LC system displayed a 20% higher capacity retention while operating within a voltage range of 2.8 to 4.3 V. This achievement foreshadows a transformative shift in how future batteries are manufactured and utilized.

In a groundbreaking demonstration, the research team successfully implemented the APA-LC technology to produce a high-capacity 1.5 Ah pouch cell. This prototype maintained excellent discharge performance and exhibited exceptional rates during fast-charging tests, reinforcing the validity of the researchers’ approach. The combination of improved stability and capacity retention heralds a new chapter in the sustainable technology narrative, as the findings translate into practical applications.

The implications of this research extend beyond mere laboratory success; they mark a notable pivot toward truly eco-friendly battery solutions. Professor Soojin Park of POSTECH emphasizes the broader significance of their work, stating, “Our solution goes beyond merely substituting fluorinated materials; we showcase high-capacity retention and exceptional stability. This advancement will propel the battery industry towards sustainability and compliance with environmental regulations.”

Further, Young-Ho Yoon of Hansol Chemical underlines the strategic market position achieved through addressing pressing PFAS regulatory matters, with projections indicating substantial growth in the global cathode binder sector by 2026. Their ongoing research and collaboration stand to fortify their status as leaders in eco-friendly battery materials.

The advent of the fluorine-free APA-LC battery system provides more than just a technical innovation; it embodies a crucial step towards an environmentally responsible energy future. As engineers and chemists unite to navigate the challenges of the battery industry, the future is decidedly bright for sustainable technologies.

Leave a Reply