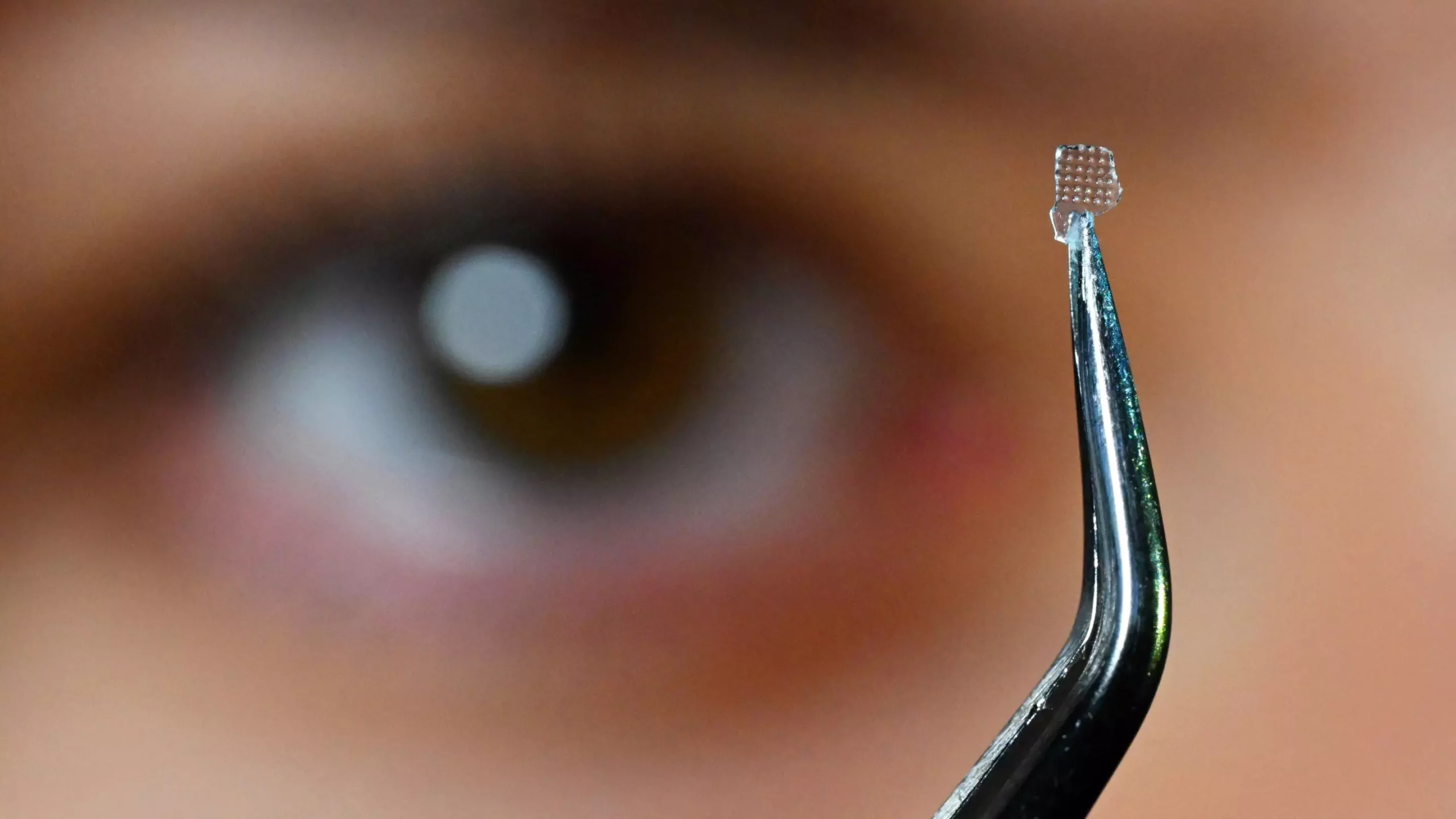

In an era where technology constantly adapts and evolves, a remarkable innovation from the University of Jena puts forth a groundbreaking concept. The research team has ingeniously created a micro-optical lens, mere millimeters in size, that reacts to gaseous environments. This optical lens doesn’t merely serve as a passive device; instead, it exhibits a dynamic refractive behavior triggered by the absorption of gas. Such functionality enhances our understanding of optics in multifaceted ways, promising potential applications that could reshape industries.

The Hybrid Glass Marvel

At the heart of this innovation lies a hybrid glass material, possessing a unique three-dimensional lattice structure. This architecture is pivotal; it houses microscopic cavities capable of accommodating gas molecules, thus altering the optical properties based on gas presence. Professor Lothar Wondraczek highlights the novelty of this approach, emphasizing the multi-responsive nature of the material. By facilitating light refraction that adjusts with gas absorption, the lens represents a revolutionary stride toward intelligent optical systems capable of real-time feedback.

The research team faced considerable hurdles. Traditional glass-forming techniques needed to be redefined to suit the specificity of hybrid glass. Notably, the researchers delved into the complex realm of metal-organic frameworks, which are typically utilized for gas storage or separation, but often fall short due to their vulnerability to heat. This aspect posed a significant barrier; the challenge was to synthesize materials that maintain integrity under temperature fluctuations.

Innovative Synthesis Processes

Doctoral candidate Oksana Smirnova, together with Dr. Alexander Knebel, pioneered a sophisticated synthesis process that allowed them to achieve high-purity materials essential for effective optical performance. The innovation did not stop there; the research team employed advanced techniques, including 3D printing for mold creation, to shape the materials into desired geometries efficiently. This meticulous method of material shaping showcases an intriguing blend of chemistry and engineering, allowing unprecedented customizability in optical design.

This methodology facilitates the production of not just micro-lenses but a variety of lens shapes, broadening the scope for application. This versatility makes the developed lens a tantalizing prospect for fields requiring sensitive optical components. The researchers propose that their design could also be funneled into logical circuits, where reactions depend on simultaneous conditions. This dual response to both light and gas presents a sophisticated level of interaction that traditional materials cannot match.

Broadening Horizons for Functional Materials

Looking beyond micro-lenses, this innovation holds significant ramifications for other applications, notably such as membranes designed for gas separation. Optical properties that fluctuate with varying gas concentrations could lead to smarter, more efficient industrial processes.

This emerging technology challenges conventional boundaries, as the application potential extends into realms not yet fully realized. By demonstrating that materials can react to their environment in complex ways, the research from the University of Jena champions a forward-thinking approach to materials science. As intelligence in materials amplifies, we can anticipate an era where optics and chemistry converge more profoundly, fostering a future where responsive technologies redefine our understanding and interaction with the world.

Leave a Reply