In a significant breakthrough for the recycling industry, a team led by Professor James Tour at Rice University has devised a novel method for extracting valuable metals from electronic waste (e-waste). This innovative technique promises to enhance the efficiency of metal recovery while minimizing the environmental footprint commonly associated with traditional recycling practices.

The increasing volume of e-waste—a byproduct of rapid technological advancement—presents a critical challenge. Each year, millions of tons of discarded electronics release toxic substances into the environment, further compounding the issues associated with mining for raw materials. Tour emphasizes that their new method could potentially alleviate some of these pressing challenges, stating, “Our process offers significant reductions in operational costs and greenhouse gas emissions,” underlining its pivotal role in sustainable recycling.

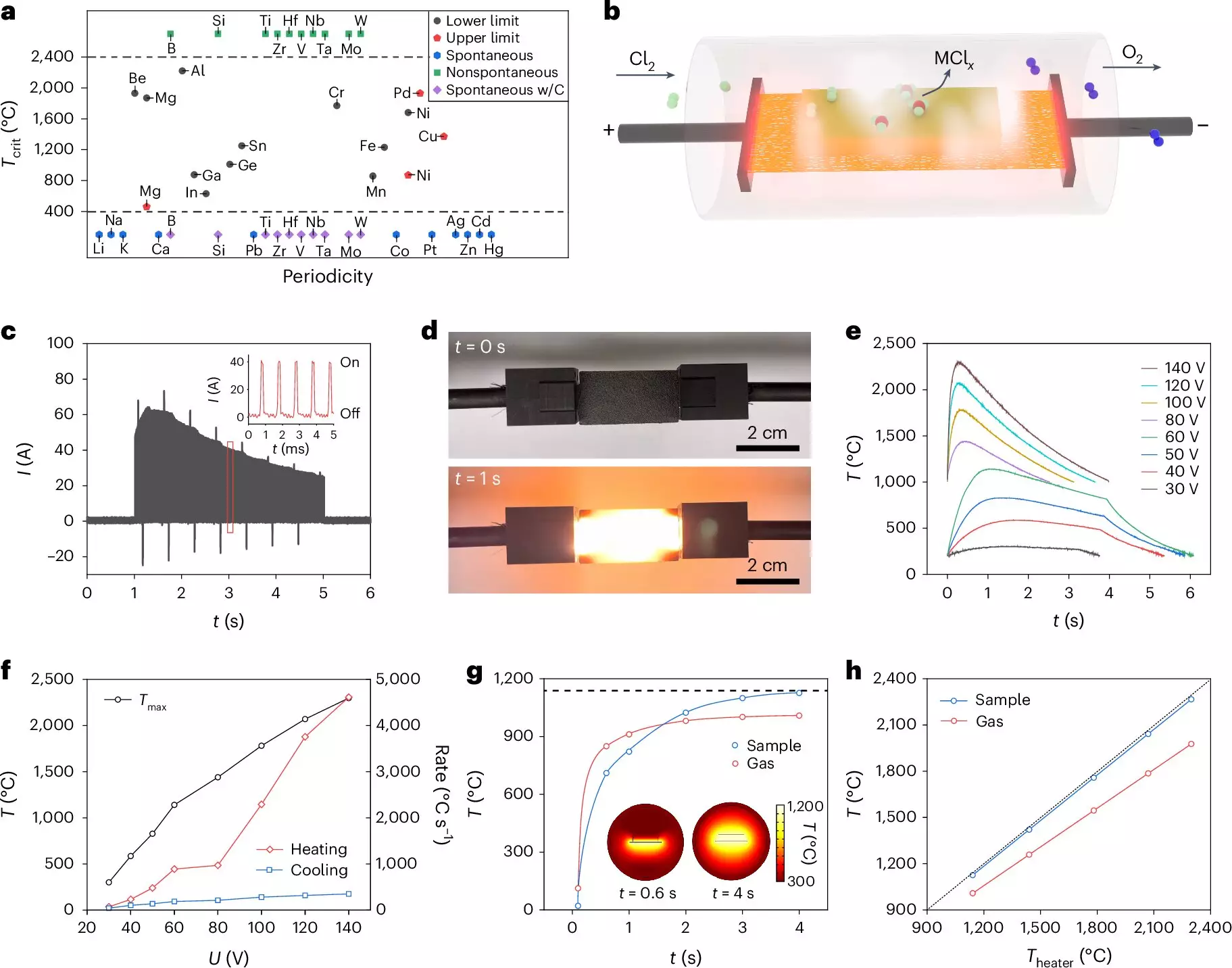

Traditional recycling techniques, such as hydrometallurgy and pyrometallurgy, although effective, are energy-intensive and generate hazardous waste, primarily due to their reliance on harsh chemicals and large volumes of water. In stark contrast, the method introduced by Tour’s team leverages flash Joule heating (FJH)—a process that uses electrical currents to rapidly heat materials to extreme temperatures, effectively transforming e-waste into recoverable metals.

By integrating chlorination processes with FJH, the researchers have successfully extracted metals such as gallium, indium, and tantalum from various electronic components. This method boasts impressive results, achieving a metal purity exceeding 95% and yields above 85%, showcasing its potential as a scalable solution in the recycling sector.

One of the notable achievements of this research is its potential impact on global metal supply chains. The ongoing demand for critical metals has raised alarms over shortages that could hinder technological progress. Co-authors of the study, including postdoctoral researchers Shichen Xu and Bing Deng, highlight the importance of their findings by stating that this method not only addresses the immediacy of critical metal shortages but also does so in an economically viable way.

The promising nature of this research extends to other metals as well, with plans for adapting the methodology to recover lithium and rare Earth elements, both of which are integral to modern technologies, including batteries and electronic devices. This broader applicability hints at a transformative wave for recycling protocols across the industry.

A Sustainable Future for Electronic Waste Management

The implications of this research resonate far beyond mere waste management. By significantly reducing the environmental impacts of traditional metal recovery methods, it aligns with goals of sustainability and conservation. As the global appetite for electronic devices continues to grow, implementing such innovative recycling techniques could lead to more responsible consumption patterns and help preserve natural ecosystems.

The work by Rice University’s research team stands as a testament to the potential interdisciplinary collaborations that can yield solutions to some of the planet’s most daunting challenges. As we tackle the accumulating crisis of electronic waste, methods that merge efficiency with sustainability, like those developed by Tour and his colleagues, will be crucial in shaping a greener future.

Leave a Reply