Catalysts are integral to the production of countless chemical products that permeate our daily lives, playing a crucial role in accelerating reactions across various industrial processes. Remarkably, more than 90% of chemical manufacturing relies on these extraordinary substances. By decreasing the energy input and sometimes enabling reactions that would otherwise not occur, catalysts stand as unsung heroes of the chemical industry. As global industries strive for greater efficiency and sustainability, the quest for improved catalyst technology has never been more vital.

Researchers at the Karlsruhe Institute of Technology (KIT) have unveiled an exciting breakthrough regarding noble-metal catalysts, a category known for their effectiveness and applicability in critical industrial processes. This innovative concept significantly enhances the stability of these precious metals while simultaneously reducing their overall consumption. As documented in the esteemed journal Angewandte Chemie, this research represents a major step toward sustainable resource management in chemical production. Dr. Daria Gashnikova, a leading researcher at KIT’s Institute for Chemical Technology and Polymer Chemistry (ITCP), articulated the potential impact of this research, emphasizing that it will promote the longevity and efficiency of catalysts with minimal noble metal usage.

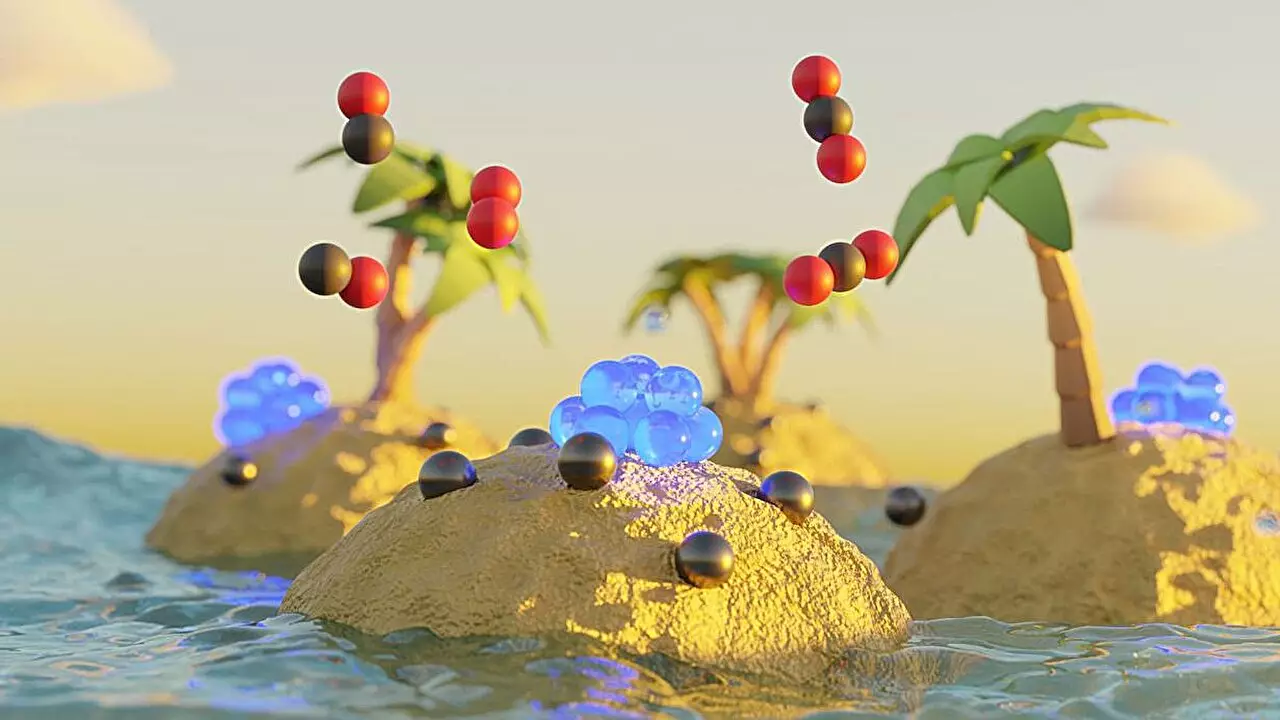

The backbone of this groundbreaking research lies in the detailed examination of supported catalysts, where catalytic materials are dispersed as fine nanoparticles on a support substrate. These nanoparticles are not static; their dynamic nature means that their structures can change based on reaction conditions. Such variability, however, presents significant challenges. For instance, particles can coalesce into larger aggregates, diminishing the number of active sites available for reactions. Conversely, they may disintegrate into single atoms that lack catalytic effectiveness. In either scenario, these transformations adversely impact catalytic performance, leading to inefficiencies and increased resource use.

Enhancing Stability through Strategic Interactions

The novel approach developed by the KIT researchers addresses these performance issues by leveraging the different interactions between noble metals and various support materials. By optimizing these interactions, they aim not only to maintain the integrity of noble-metal clusters but also to enhance their activity even when used in minimal quantities. This technique promises to preserve the active sites necessary for catalytic reactions, ensuring that chemical processes remain effective while adhering to increased sustainability standards.

The Implications for a Sustainable Future

The broader implications of this research extend far beyond the laboratory. Implementing more efficient catalysts with reduced noble metal requirements paves the way for a more sustainable chemical industry. As the world grapples with resource scarcity and environmental challenges, advancements such as these align with global efforts to reduce material waste and enhance energy efficiency. By refining our approach to catalysts, we do not merely push the boundaries of chemical engineering; we also play a crucial role in the collective movement toward a greener, more sustainable future.

The work from KIT represents a promising leap in catalysis technology, emphasizing that innovation must work hand-in-hand with sustainability to address today’s pressing environmental issues.

Leave a Reply