As summer approaches, the sweltering heat can pose challenges for anyone who ventures outdoors, whether they are athletes, children playing at the park, or beach enthusiasts. Many have experienced the discomfort of clothing that absorbs rather than reflects the sun’s heat. Traditional cooling fabrics, often made from specialized fibers or involving complex manufacturing methods, have been limited in accessibility and sustainability. A team of researchers from the University of Massachusetts Amherst has now pioneered a solution: a durable chalk-based coating that can reduce the air temperature beneath treated fabrics by as much as 8 degrees Fahrenheit.

Outdoor heat exposure is a well-recognized discomfort that exacerbates the risks of heat-related illnesses. As sunlight strikes the skin and clothing, ultraviolet (UV) and near-infrared (near-IR) light contributes to the rising temperature. Trisha L. Andrew, a chemist and materials scientist involved in the research, highlights the dual challenge in outdoor settings — not only does the body generate its own heat, but clothing worsens the situation by absorbing additional thermal energy.

To combat this issue, scientists have been investigating methods to create fabrics that can deflect solar radiation while also facilitating the release of body heat. This interplay between deflection and cooling is termed radiative cooling, which leverages specific materials to achieve a comfortable outdoor experience without the need for artificial cooling methods.

Traditionally utilized materials in high-performance cooling textiles often include synthetic particles like titanium dioxide or aluminum oxide embedded within the fibers. While these are effective, they rely on complex manufacturing processes that raise sustainability concerns. Moreover, many existing options incorporate perfluoroalkyl and polyfluoroalkyl substances (PFAS), commonly known as “forever chemicals,” which have gained notoriety due to their environmental persistence and harmful effects.

Driven by the need for a more eco-friendly solution, Andrew posed a challenge to her team: could they develop a textile coating using natural, benign materials? This inquiry led to a groundbreaking idea — to use calcium carbonate, a naturally occurring mineral found in chalk, to create a cooling effect without the adverse environmental impacts associated with current methods.

The crux of the innovation rests on a technique called chemical vapor deposition (CVD), previously utilized by Andrew’s team to apply durable polymer coatings on fabrics. This method simplifies the coating process by combining synthesis and application in one step, resulting in a more environmentally conscious manufacturing process.

Inspired by traditional limestone plasters that have historically kept homes cool in hot climates, graduate students Evan D. Patamia and Megan K. Yee undertook the challenge of integrating calcium carbonate and barium sulfate into their polymer systems. These compounds possess reflective properties necessary for cooling, with calcium carbonate targeting visible and near-IR wavelengths, while barium sulfate reflects UV light.

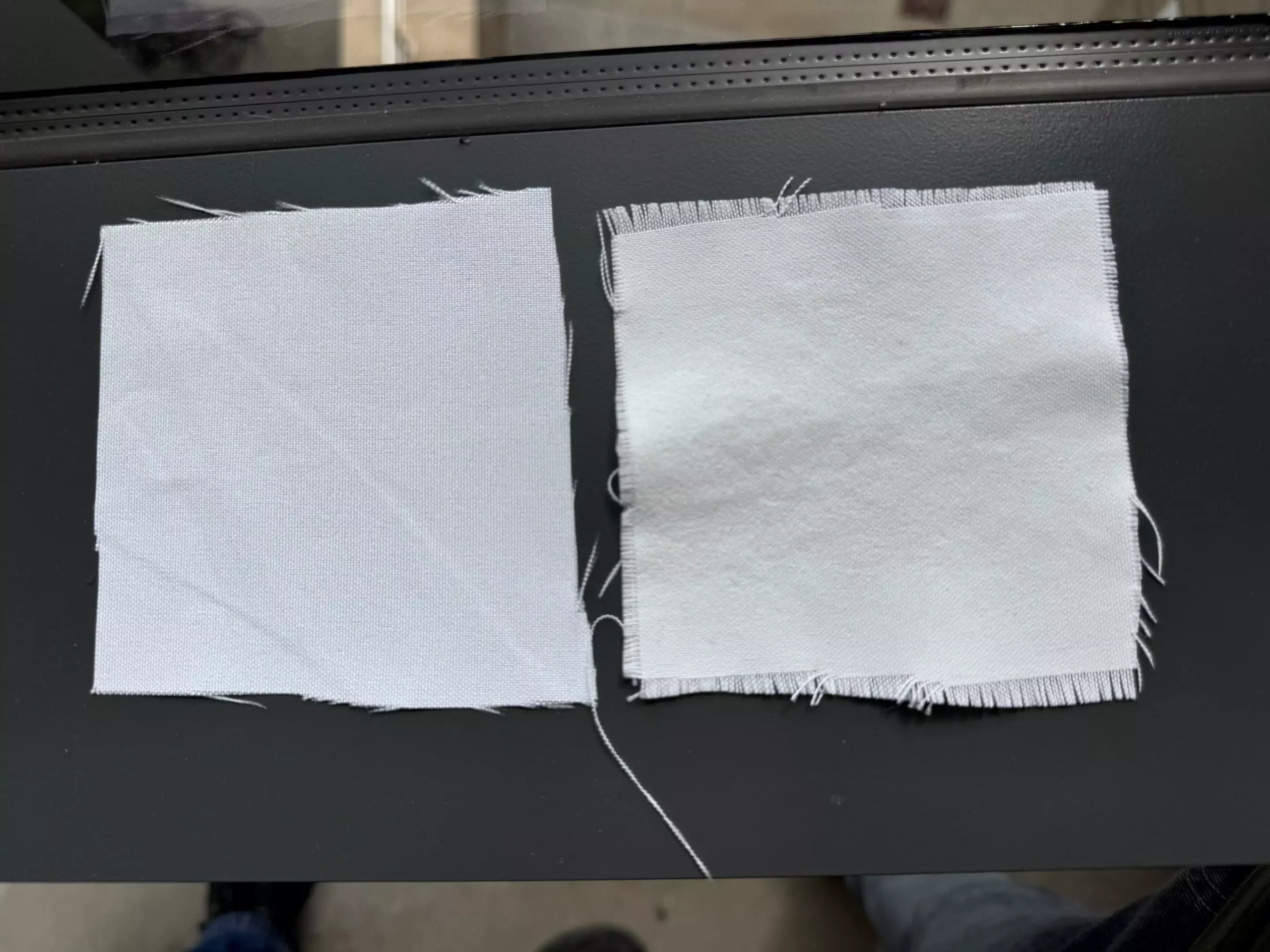

By treating small fabric samples with a thin layer of polymer and successively dipping them into solutions containing the desired minerals, the coating developed a matte finish and improved cooling properties. This systematic approach allowed the researchers to control the particle size and distribution, optimizing the coating’s effectiveness in reducing heat absorption.

To evaluate the effectiveness of their new cooling fabric, the research team performed tests outdoors on days surpassing 90 degrees Fahrenheit. Air temperatures recorded under the treated fabric indicated drastic cooling, with measurements registering up to 8 degrees Fahrenheit lower than the surrounding environment. In certain instances, the temperature differential reached a remarkable 15 degrees Fahrenheit, highlighting the substantial impact of their innovative coating.

Patamia expressed excitement over the palpable cooling sensation experienced beneath the treated fabric, likening it to standing in the shade — a welcome relief on hot summer days. Furthermore, durability testing mimicking the conditions of washing machines indicated that the chalk-based coating maintained its integrity and cooling capabilities even after exposure to friction and detergents, making it practical for everyday use.

While the current laboratory equipment limits the scale at which the team can produce these coatings, Andrew is actively engaged in a startup that aims to broaden the application of this technology. The potential to apply this unique coating to commercially available fabrics presents an opportunity to revolutionize the textile industry, particularly in regions struggling with extreme heat.

The innovative chalk-based coating represents a leap forward in the pursuit of comfortable and sustainable outdoor textiles. By utilizing natural ingredients and straightforward application methods, this research team has opened doors to a future where staying cool outdoors may no longer be a luxury, but rather an achievable standard. This technology not only fortifies personal comfort but also carries significant implications for public health, particularly as global temperatures continue to rise.

Leave a Reply