Plastic pollution has emerged as one of the most pressing environmental challenges of our time, with the staggering amounts of plastic waste affecting ecosystems globally. Among the various types of plastics, polyethylene terephthalate (PET) predominates, largely due to its widespread application in textiles and packaging. Despite ongoing initiatives to enhance recycling efforts, the effectiveness of material recycling remains woefully inadequate, particularly when it comes to breaking down these materials into their basic building blocks for reuse. Recent advancements in chemical recycling methods are showing promising potential to transform this landscape.

A pivotal breakthrough has been achieved by a research team led by Professor Kotohiro Nomura at Tokyo Metropolitan University. The team developed a novel method for the depolymerization of PET using alcohols and an inexpensive iron trichloride catalyst, thereby revealing a cost-effective and environmentally friendly route for recycling plastic waste. This transformative research, published in the journal *Industrial Chemistry & Materials*, embarks on a mission to address the pressing need for efficient recycling strategies, particularly targeting PET found in both plastic waste and mixed textile materials.

Redefining Depolymerization Techniques

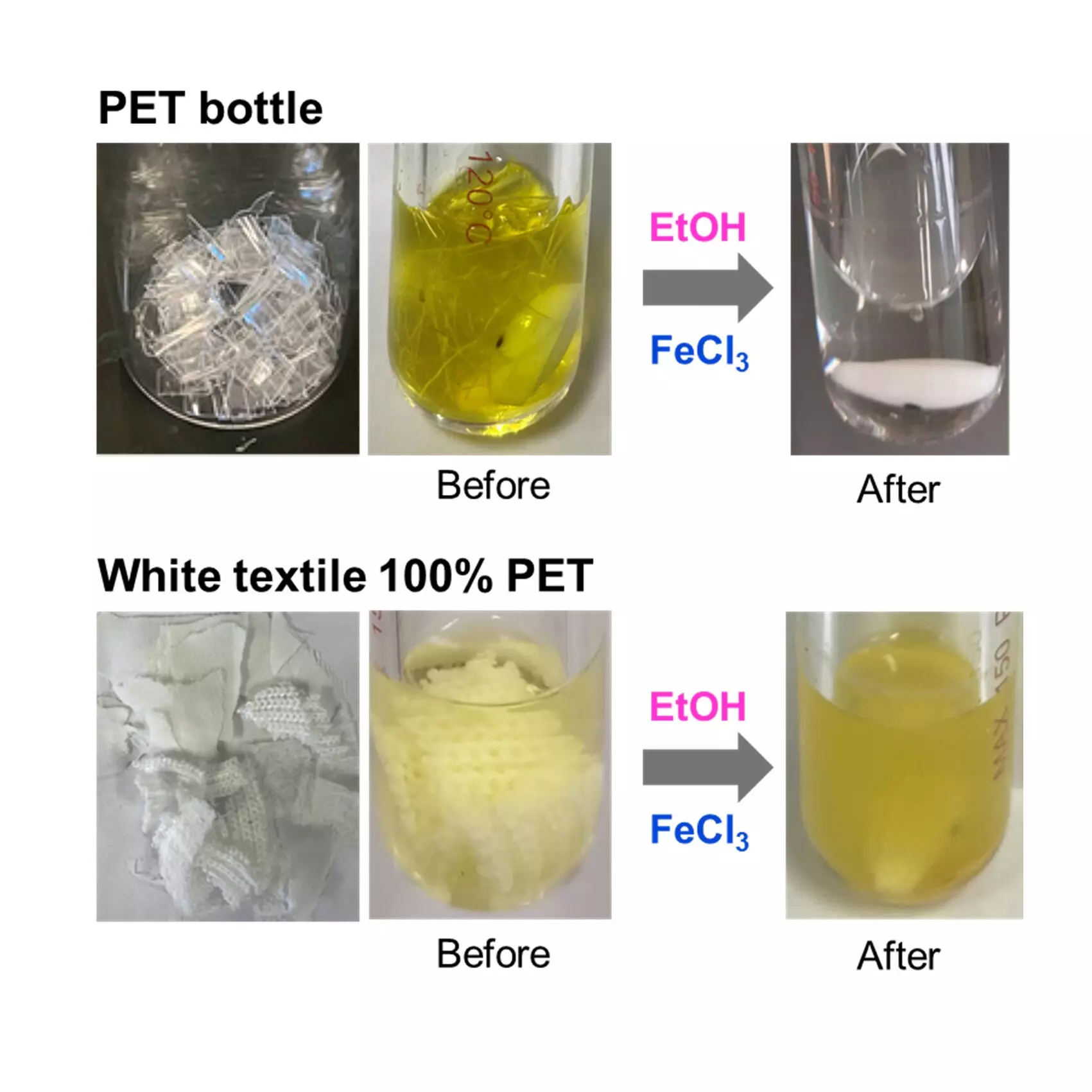

Traditionally, the depolymerization of polyesters has required substantial heat and various acid or base catalysts, which often complicate the process. However, Nomura’s team has identified a simple method that operates without these harsh conditions. By utilizing ethanol along with FeCl3 or FeBr3 as catalysts, their process achieved an impressive depolymerization selectivity of 98-99%, ultimately producing diethyl terephthalate (DET) and ethylene glycol (EG) from PET. Notably, this method functions effectively at lower temperatures ranging from 160–180°C, making it more feasible for practical applications.

Implications for Textile Waste Recycling

One of the most significant aspects of this research is its application to textile waste, a category notoriously challenging for recycling due to its complex composition, primarily involving polyester and natural fibers like cotton. The introduced technique allows for the selective extraction of PET from these hybrid materials, enabling efficient recovery of cotton while converting PET components back to useful raw materials. This capacity to selectively depolymerize PET from blended materials is a remarkable step towards sustainable textile waste management, addressing both environmental concerns and economic feasibility.

The rise of circular economy initiatives underscores the urgent need for innovative recycling methodologies. By converting waste back into valuable raw materials, this new depolymerization technique represents a significant contribution toward closing the loop in plastic and textile production cycles. The strategic involvement of an easily accessible catalyst like iron trichloride not only enhances the method’s applicability on a global scale but also emphasizes the potential for scalable industries.

The research led by Professor Nomura exemplifies the forward strides being made in the field of chemical recycling. By presenting a straightforward, efficient, and environmentally friendly approach to PET depolymerization, this innovative method opens new avenues for addressing the critical issues surrounding plastic waste. As the implications of this work resonate across both academic and industrial communities, it highlights a pathway toward a more sustainable future—where recycled materials can seamlessly reintegrate into production cycles, fostering a healthier planet for generations to come.

Leave a Reply