Lithium-ion batteries (Li-ion) have revolutionized energy storage technologies, primarily due to their high energy density and efficiency. Among the various materials employed for cathodes, Nickel Cobalt Manganese 811 (NCM811) has emerged as a top contender. However, these poly-crystalline materials face significant challenges in terms of structural integrity and lifespan. The formation of cracks due to mechanical stresses can lead to the premature degradation of active materials, directly affecting the battery’s performance and longevity.

Understanding how the structure of NCM811 evolves under operational conditions is crucial for improving its performance. The mechanical stress within the material can lead to significant issues, particularly during the (de)lithiation process, where lithium ions are inserted and withdrawn from the structure. This study highlights the necessity of ongoing monitoring of the chemo-mechanical behavior of NCM811 to identify and mitigate factors leading to mechanical failure.

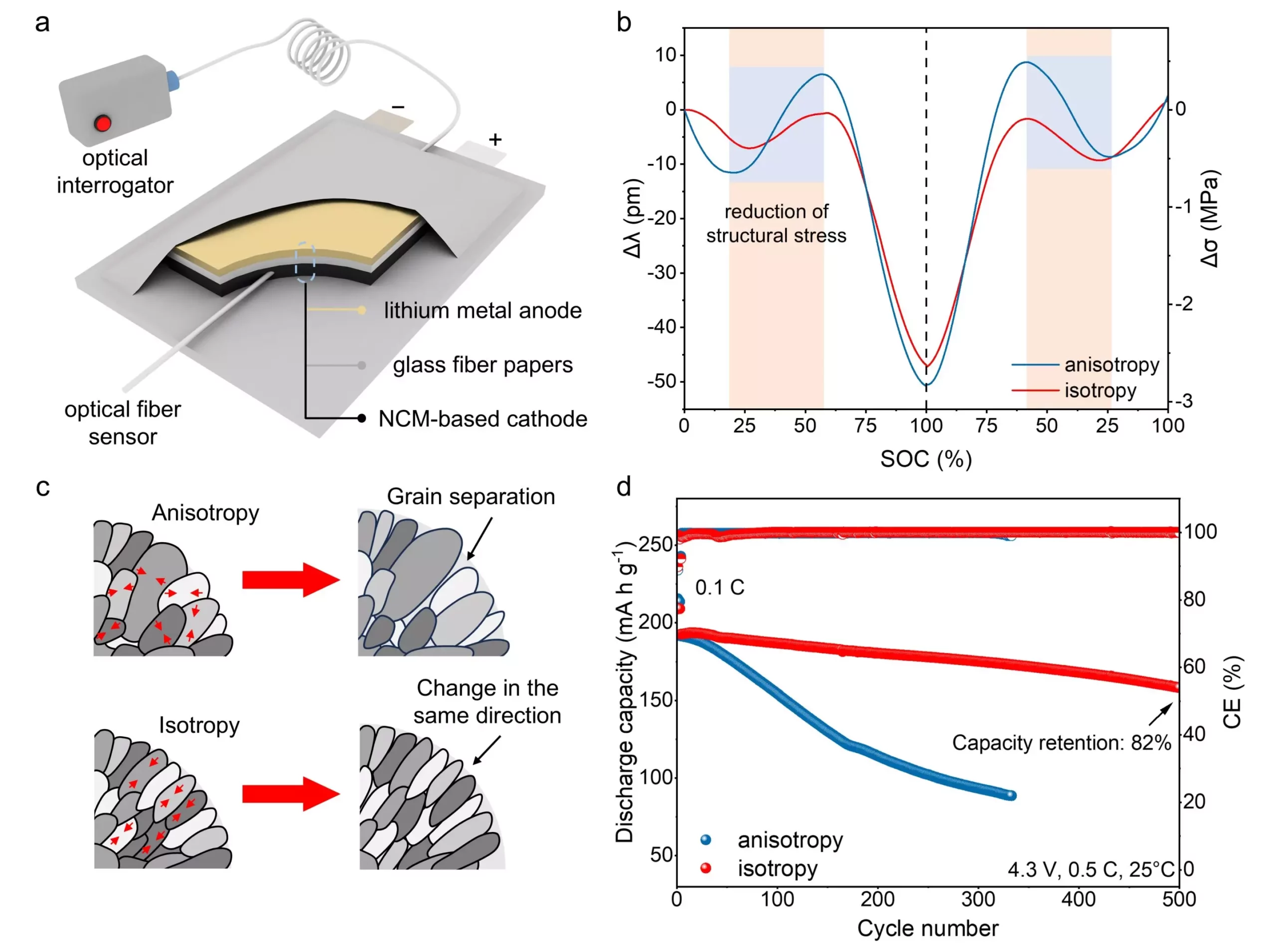

To comprehend these stresses in real-time, a research team led by Prof. Yunhui Huang and Prof. Zhen Li has pioneered a novel approach by integrating optical fiber sensing directly into the battery architecture. This innovative method allows for in operando detection of stress changes specifically in the NCM811 cathode. The fiber is designed to be chemically stable and compact, ensuring that it does not interfere with the battery’s overall performance while transmitting accurate data regarding internal stresses.

Through this comprehensive investigation, it has been established that the stress experienced by NCM811 materials falls primarily into two categories: chemical and structural. Chemical stresses occur naturally during the cycling of the battery, yet it’s the structural stress that poses a more significant threat by causing cracks detrimental to electrochemical performance. By analyzing how structural stress is generated—especially through factors like the anisotropy among primary particles and fluctuations in the crystal c-axis during lithiation—researchers have pinpointed crucial areas that require strengthening.

An exciting outcome of this research is the suggestion to enhance the anisotropy of the primary particles. By engineering an organized arrangement of these particles within the poly-crystalline structure, it is possible to reduce the generation of structural stress significantly. Notably, this modification has demonstrated exceptional results, with samples retaining a capacity of 82% even after 500 cycles at a discharge rate of 0.5C. This level of performance illustrates the potential benefits of structural optimization in cathode materials.

The integration of optical sensing represents a frontier in the monitoring and optimization of battery performance. As Prof. Huang articulates, the insights gained from these advancements not only decode the complex interplay of mechanical and chemical stresses but also guide the creation of more robust battery materials. Ultimately, the future of battery technology may hinge on such innovative methodologies, leading to safer, smarter, and longer-lasting energy solutions. As the quest for advanced battery technology evolves, ongoing research and development will be essential in addressing the challenges posed by material degradation in high-energy-density applications.

Leave a Reply