In recent years, the study of biological systems has revealed remarkable insights into how nature creates durable and resilient materials. A significant focus has been on the structural mechanics of organic forms, such as sea sponges, which display an astonishing ability to integrate stiffness and flexibility through layered growth patterns. This interplay of materials creates a sturdy framework that can endure substantial stress without compromise. A prominent voice in this field is Nancy Sottos from the Beckman Institute for Advanced Science and Technology, who states, “Nature has a way of turning brittle materials into tough ones through intricate patterning.” This leaves us wondering how we can emulate such designs in synthetic materials.

The Influence of Nature on Synthetic Models

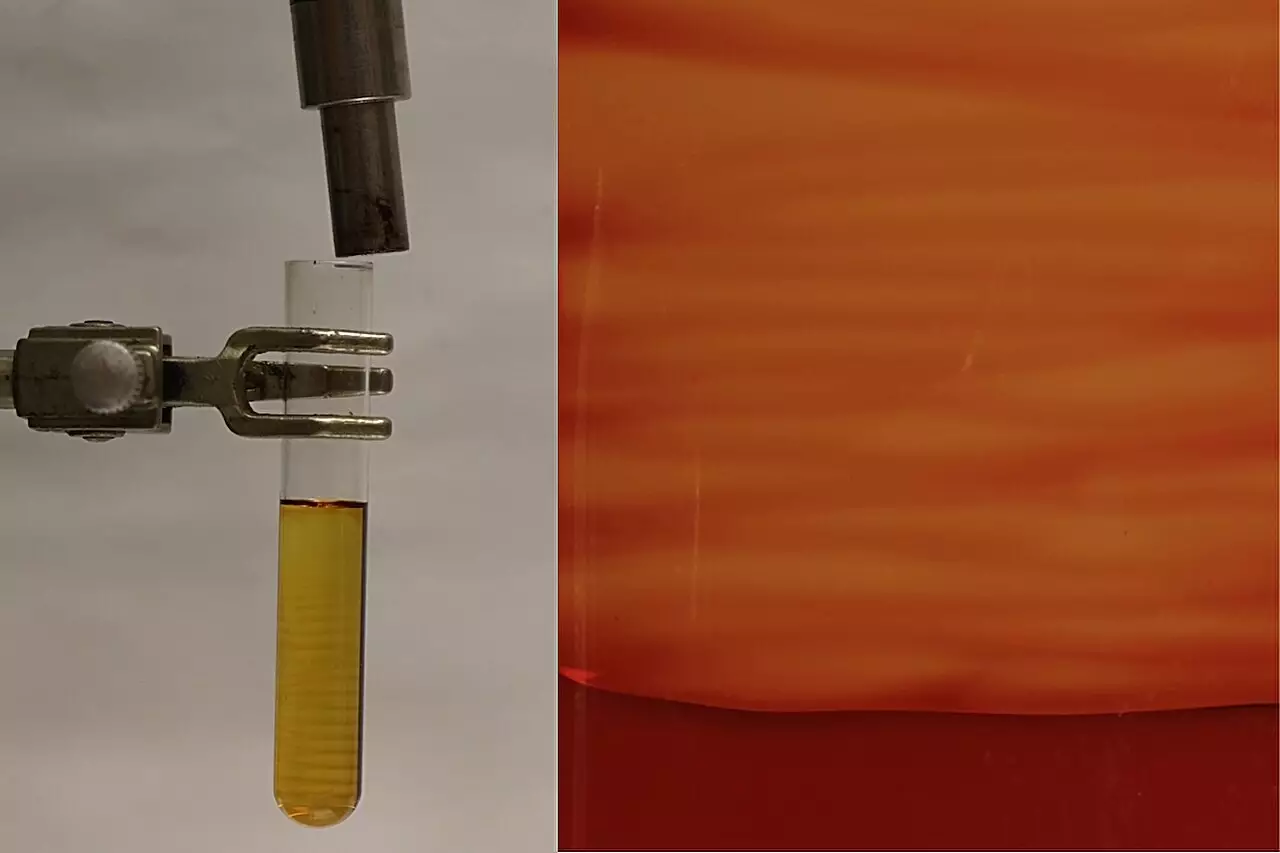

In a recent article published in *Nature*, Sottos and her team at the University of Illinois Urbana-Champaign delve deeper into this inquiry by exploring a fabrication method known as frontal polymerization, which utilizes heat to catalyze a chemical process that generates polymers. Building on their prior work from 2021 that established frontal polymerization as a viable approach for creating biologically-inspired materials, this new research refines the method further. It allows for the meticulous formation of crystalline structures within the polymer matrix, which markedly improves the toughness and durability of the resulting materials.

Sottos posits that “Patterned materials often contain both stiff and soft regions,” which promotes resilience under varying stress. By mimicking the spontaneous yet efficient designs found in nature, researchers can produce synthetic materials that possess similar mechanical properties. The study emphasizes how such hybrid materials can outperform conventional options, which typically lack this flexibility in structure.

The groundbreaking work conducted by Sottos and her colleagues showcases the capabilities of morphogenic manufacturing techniques in the development of advanced materials. Lead author Justine Paul recounts the challenges faced when trying to ascertain the ideal conditions for achieving the desired crystalline configurations. “Efforts to determine optimal reaction conditions took several weeks,” she explains, highlighting the labor-intensive nature of this process. The persistence paid off, resulting in a polymer material that exhibits both amorphous, less-structured components and well-defined crystalline regions.

This combination reinforces the concept that the resilience of a product can often be traced back to stark contrasts within its makeup. Just as a sea sponge maintains its integrity through a blend of rigid and flexible parts, these newly developed polymers manifest unique structural properties, rendering them suitable for a variety of applications.

One of the most striking aspects of this research is its embodiment of interdisciplinary collaboration. The contributions from various experts were vital to the project’s success. Cecilia Leal’s application of X-ray scattering has provided critical insights into how the polymer chains interact within the patterned material. “Deciphering holistic structure-property relationships from molecule to matter is essential,” she notes, underscoring the interconnected nature of this research.

Philippe Geubelle’s role focused on modeling the manufacturing process to understand the thermo-chemical instabilities that facilitate the development of heterogeneous materials. This alignment of experimental practice with theoretical modeling exemplifies how efforts across different scientific disciplines can coalesce to yield significant technological advancements.

The Significance of Teamwork in Material Science

The collaborative ethos at the Beckman Institute serves as a noteworthy backdrop for these advancements. As described by Jeff Moore, a core team member, it is this unified environment that has allowed such breakthroughs in materials science to flourish. “Our work demonstrates a new frontier—patterning materials without molds or milling, resulting in unique properties that arise from this added structure,” he states.

This interdisciplinary initiative doesn’t just highlight the functionality of the materials themselves; it reflects a larger narrative about the importance of cooperation in scientific endeavors. As investigations continue, integrating various scientific dimensions not only enhances our understanding but also paves the way for creating innovative materials that could redefine multiple industries, including aerospace and construction.

The study of biological materials is reshaping our perception of synthetic alternatives. By embracing nature’s designs, researchers are not just creating better materials—they are setting the stage for an era where collaboration and innovation drive the future of material science. Through the marriage of biology and technology, we are unlocking new possibilities that were once considered inconceivable.

Leave a Reply