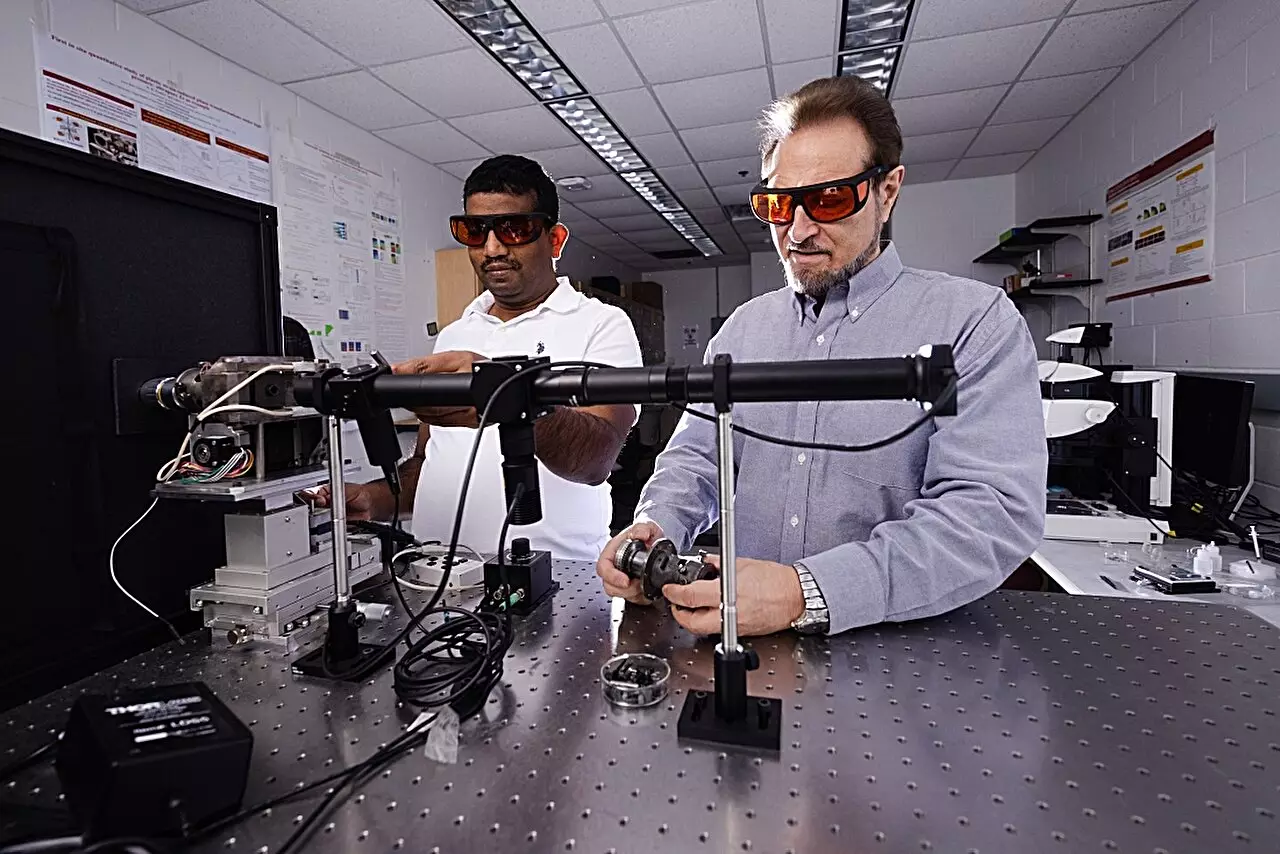

In the ever-evolving field of material science, research often hinges on the ability to manipulate substances under extreme conditions. A notable figure in this domain is Valery Levitas, a dedicated researcher who left Europe in 1999 with a diamond anvil cell, a sophisticated tool designed to subject materials to high pressure. Fast forward to today, Levitas and his team at Iowa State University have refined and enhanced this work, delving into the microscopic transformations that materials undergo when exposed to such forces. Their recent study highlights significant findings regarding silicon, a vital component in the electronics sector, particularly focusing on how it behaves under conditions of pressure and shear.

The fundamental question driving this research is: how does the application of pressure alter the structural properties of materials like silicon? Under typical circumstances, the transformation of silicon’s crystal structure to new phases would require immense pressures; however, Levitas’s findings suggest a paradigm shift in this understanding. By employing a method that includes both shear deformation and pressure application, the research team uncovered that transformations could occur at dramatically lower pressures than previously thought.

In their experiments, they subjected silicon particles of varying sizes—ranging from 1 millionth of a meter to 100 billionths of a meter—to the unique strains generated by the diamond anvil cell. The results showed that traditional notions of pressure thresholds could be re-evaluated. For instance, the transformation from silicon’s “Si-I” phase to the “Si-II” phase under conditions of only 0.3 gigapascals signifies a remarkable reduction from the substantially higher pressure of 16.2 gigapascals typically required in previous studies. This discovery provides a glimpse into a new avenue of research where lower forces yield substantial changes in material properties.

A critical distinction made in Levitas’s research is between altering the physical dimensions of the material versus its internal microstructure. The team posited that the real transformation occurs at the microstructural level, which then triggers various phase changes. This understanding suggests that it is not merely the force applied but how that force interacts with the atomic arrangement within the material that yields different properties. By changing the microstructure, new phases can emerge, each with unique characteristics that could be leveraged for practical applications.

Understanding the various crystal lattice structures—seven phases of silicon are examined—is crucial, as they dictate the material’s properties and potential functionalities. The implications of this research extend far beyond theoretical exploration; by tapping into these low-pressure methods, industries could develop new materials that possess optimal electronic, optical, and mechanical properties tailored for specific applications.

The practicality of high-pressure techniques has long been a barrier for industries seeking to utilize advanced materials. Traditional methods often require impractically high pressures, making them economically unviable. However, Levitas and his collaborators have opened doors to new possibilities by demonstrating that effective material transformations can occur using more manageable pressure levels in combination with plastic deformations. This innovative approach not only simplifies the manipulation of materials but also significantly reduces costs associated with high-pressure processes.

As the researchers noted, the ability to access high-pressure phases at modest pressures could lead to the production of novel nanostructured materials, potentially revolutionizing the electronics industry. The opportunity to create composites with ideal properties opens avenues for advancements in technology, from improved semiconductors to innovative electronic components that could enhance device performance.

After two decades of research and theoretical modeling, Valery Levitas’s findings signify a breakthrough in the understanding of material behavior under pressure. The novel techniques and methodologies employed by his team challenge existing paradigms, suggesting that innovations in material science lie in the nuances of microstructural changes rather than sheer mechanical force. As the boundaries of research expand, the potential applications for industries striving to improve material performance remain vast and exciting, paving the way for advancements that could define the future of technology.

Leave a Reply