As the world shifts towards renewable energy and technology-driven solutions, the demand for rare-earth elements (REEs) has skyrocketed. These materials, especially neodymium (Nd) and dysprosium (Dy), are integral to the production of high-performance magnets vital for electric vehicles (EVs), wind turbines, and other green technologies. However, the extraction and recycling of REEs remain significant environmental challenges, leading researchers to seek innovative solutions that mitigate ecological damage while meeting rising demand.

Recent advancements from the Institute of Advanced Energy at Kyoto University have introduced a game-changing process called the selective extraction–evaporation–electrolysis (SEEE) process. This innovative method offers an efficient, sustainable, and less environmentally intrusive way to recycle obsolete magnets, paving the way for its application in the broader context of material recovery. Spearheaded by Professor Toshiyuki Nohira and his dedicated team, this research promises to alter the future of recycling within the tech sector, particularly in aligning practices with global carbon neutrality goals.

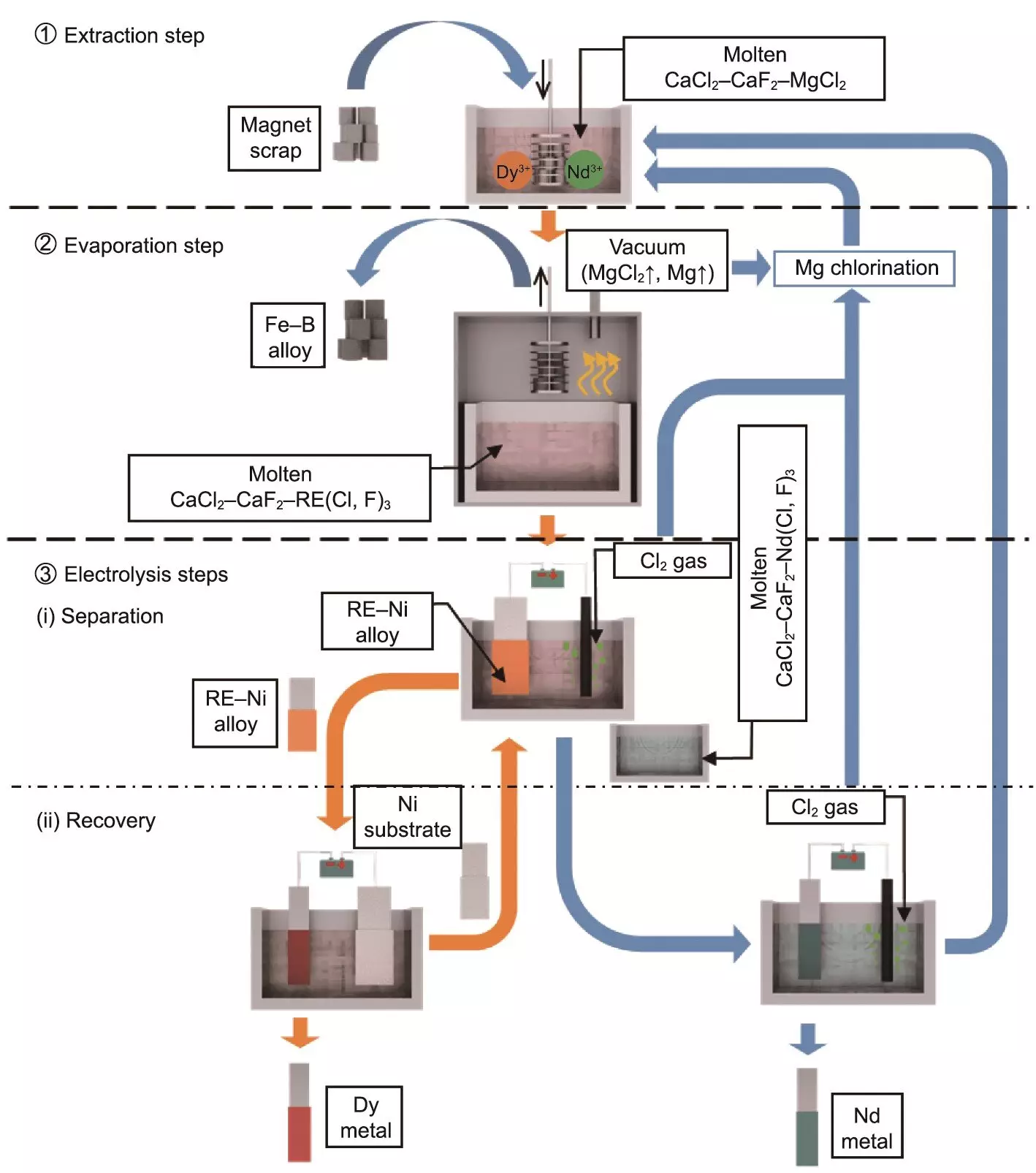

What sets the SEEE process apart from traditional recycling methods involves its three foundational steps—each meticulously designed to enhance efficiency and reduce energy consumption.

1. **Selective Extraction**: This first stage employs a specially formulated molten salt mixture that includes calcium chloride and magnesium chloride. Importantly, the addition of calcium fluoride aids in minimizing evaporation losses during extraction. By using these substances, the SEEE process effectively separates REEs from the surrounding magnet material, focusing on maximizing output while minimizing waste.

2. **Selective Evaporation**: In this phase, any residual extraction agents and byproducts are systematically removed. This step concentrates the REEs, preparing them for the final separation, ensuring that the raw materials are primed for recovery.

3. **Selective Electrolysis**: The concluding stage involves separating the extracted REEs through electrolysis, capitalizing on the unique formation potentials of each element. As a result, high-purity neodymium and dysprosium metals are generated, with recovery rates reaching an impressive 96% for neodymium and 91% for dysprosium.

Such efficiency in the recycling process not only signifies a leap forward in technological achievement but also has significant implications for resource management.

Environmental and Economic Implications

With the landscape of energy production transitioning towards a more sustainable model, the necessity for effective recycling mechanisms has never been clearer. The SEEE process stands to benefit industries reliant on REEs by mitigating the environmental costs associated with new mining operations, which often lead to habitat destruction and unfortunate ecological consequences.

Moreover, the recycling capabilities endowed by SEEE can ensure a more stable supply chain for critical materials. This element of reliability is vital for industries investing heavily in renewable technologies, such as electric vehicles and energy-efficient infrastructure. As reliance on these materials grows, the SEEE process could represent a cornerstone of sustainable practices in manufacturing and technology.

While the SEEE process has exhibited remarkable initial success in recycling neodymium magnets, its potential applications extend beyond this singular purpose. Researchers speculate that this method could be adapted for varied uses, including the reprocessing of nuclear fuels, which would significantly enhance its value across multiple sectors.

Nonetheless, as promising as these findings are, further research is essential for refining the process and fully integrating it within industrial frameworks. The ambitious vision of seamlessly incorporating the SEEE process into broader recycling practices necessitates ongoing technical evaluation and development.

A Step Towards Sustainability

The SEEE process represents a pivotal advancement in the field of rare-earth element recycling. With the global arena increasingly recognizing the urgent need for sustainable practices, innovative breakthroughs such as this highlight the importance of academic research in shaping our environmental future. The convergence of technology and sustainability will be crucial in addressing the ecological challenges ahead, and processes like SEEE are poised to lead the charge towards a greener, more responsible technological landscape.

Leave a Reply