In today’s increasingly digital world, the rise of modern integrated microelectronic devices has led to challenges in their repairability and recyclability. As the demand for electronic devices continues to surge, the environmental burden associated with their production and disposal becomes more pronounced. As a result, there is an urgent need for innovative materials that not only enhance the performance and durability of these devices but also align with the principles of a circular economy — one that emphasizes sustainability and waste reduction. A recent breakthrough in adhesive technology holds promise for addressing these pressing challenges by drawing inspiration from nature, particularly from the remarkable adhesive mechanisms found in mussels.

Debondable adhesives offer a pathway to a more sustainable future by facilitating the repair and recycling of electronic devices. These adhesives can be selectively deactivated on demand, allowing for easy disassembly without damage to the components. A collaborative research effort has yielded a new type of adhesive that possesses unique properties derived from mussel-inspired chemistry. This innovation may pave the way for smarter repair and recycling strategies that reduce electronic waste, contributing to a more sustainable electronic lifecycle.

Nature’s Ingenious Design: The Mussel Adhesive

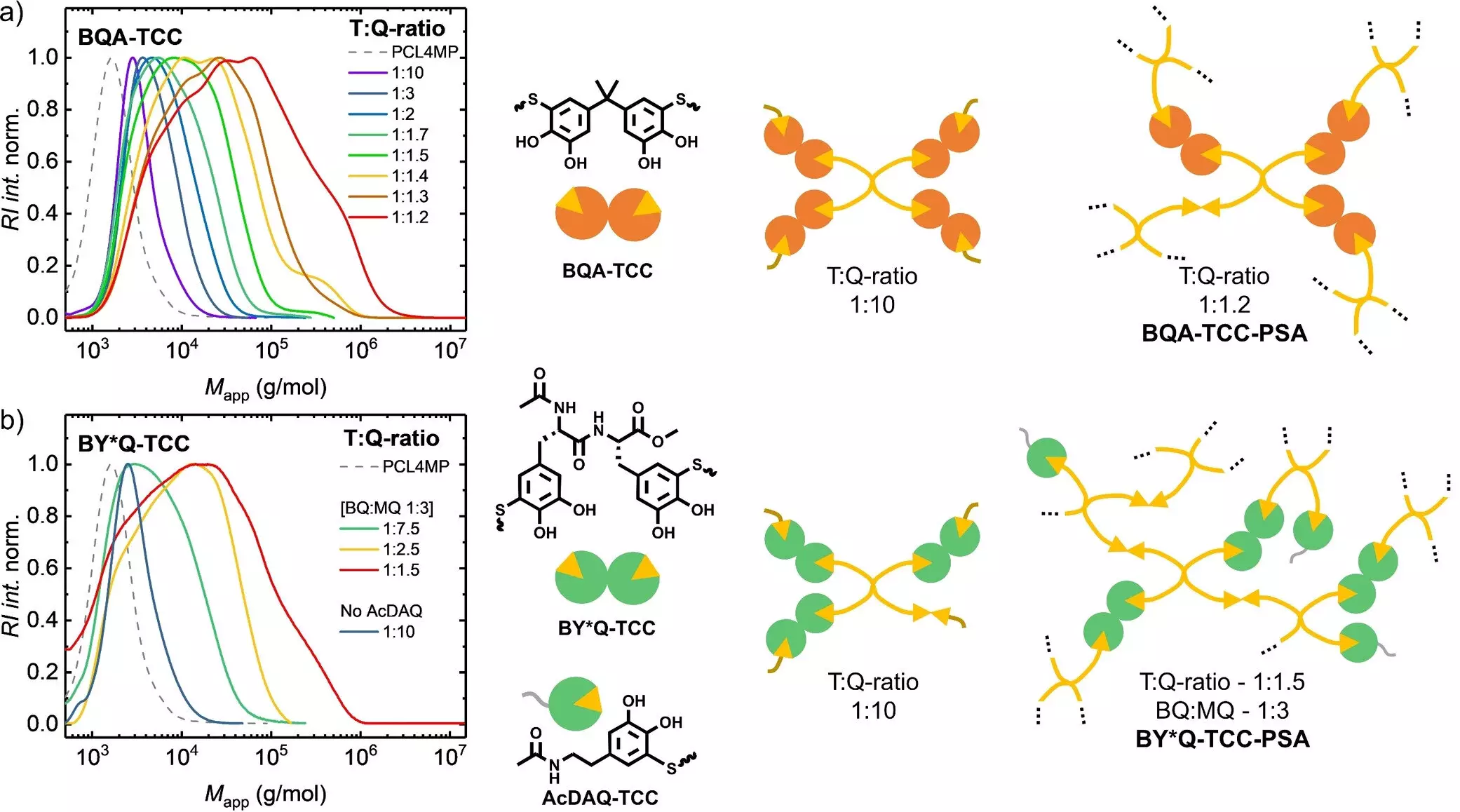

Mussels have evolved an exceptional ability to adhere firmly to a variety of surfaces, even underwater. Their secret lies in the unique chemical structure of the adhesive proteins they produce. In a parallel attempt to replicate this biological functionality, researchers have developed adhesives based on thiol-catechol polyaddition. These adhesives leverage the strong adhesion properties of thiol-substituted aromatic rings, which can form robust connections due to the presence of catechol groups. However, what distinguishes the new formulations is their ability to undergo oxidation, altering their adhesive properties dynamically.

Oxidation Mechanism: The Key to Controlled Adhesion

The innovative approach involves a two-step process where catechol groups are transformed into quinones through oxidation. This chemical transformation is crucial, as it drastically reduces the adhesion strength, enabling easier removal of adhesive residues from surfaces. Detailed analysis shows that the structural design of the adhesive monomers allows control over the polymer’s properties, lending versatility to its applications. The research team, composed of experts across various institutions, has successfully demonstrated two variants of the thermally tunable adhesive, enhancing their potential utilization in diverse environments, including underwater scenarios.

In comparing biobased peptidic biscatechol precursors with fossil-based counterparts, striking differences emerged in their adhesive performance post-oxidation. The bio-based adhesive, akin to natural mussel adhesive, presents a more effective and efficient disengagement mechanism due to its unique composition, exhibiting a 99% reduction in adhesive strength. In contrast, the fossil-derived adhesive demonstrates only a 60% decrease in adhesion strength due to its hydrophobic nature, which ironically enhances its adhesive properties. This fundamental distinction highlights the efficacy of utilizing biological principles in creating eco-friendlier materials that can address persistent challenges in electronics recycling.

Future Directions: From Chemical to Electrochemical Oxidation

Looking to the future, the research consortium aims to transition from chemical oxidation processes to direct electrochemical oxidation methods. This shift holds significant implications for the electronics repair industry, particularly for devices such as smartphones. By refining the adhesion and deactivation processes while minimizing environmental impact, we could significantly advance the viability of eco-friendly electronics. This approach not only supports the repairability of modern devices but also aligns with growing consumer expectations for sustainability.

With rising concerns over electronic waste and resource depletion, the development of innovative materials such as mussel-inspired adhesives represents a crucial step forward. The incorporation of debondable adhesives not only enhances the repairability of devices but also plays a pivotal role in fostering a circular economy. As research progresses, the potential for these adhesives to create a more sustainable electronic landscape grows, inviting a future where technology and environmental stewardship coexist harmoniously. By harnessing the wisdom of nature, we can truly affect meaningful change in the way we design, use, and dispose of electronic devices.

Leave a Reply